Injection Molding Services

- Plastic Injection Molds

- In-House Mold Builds

- Molds For Plastic Injection

- Advantages Of Molds Made In The USA

Plastic Injection Molds

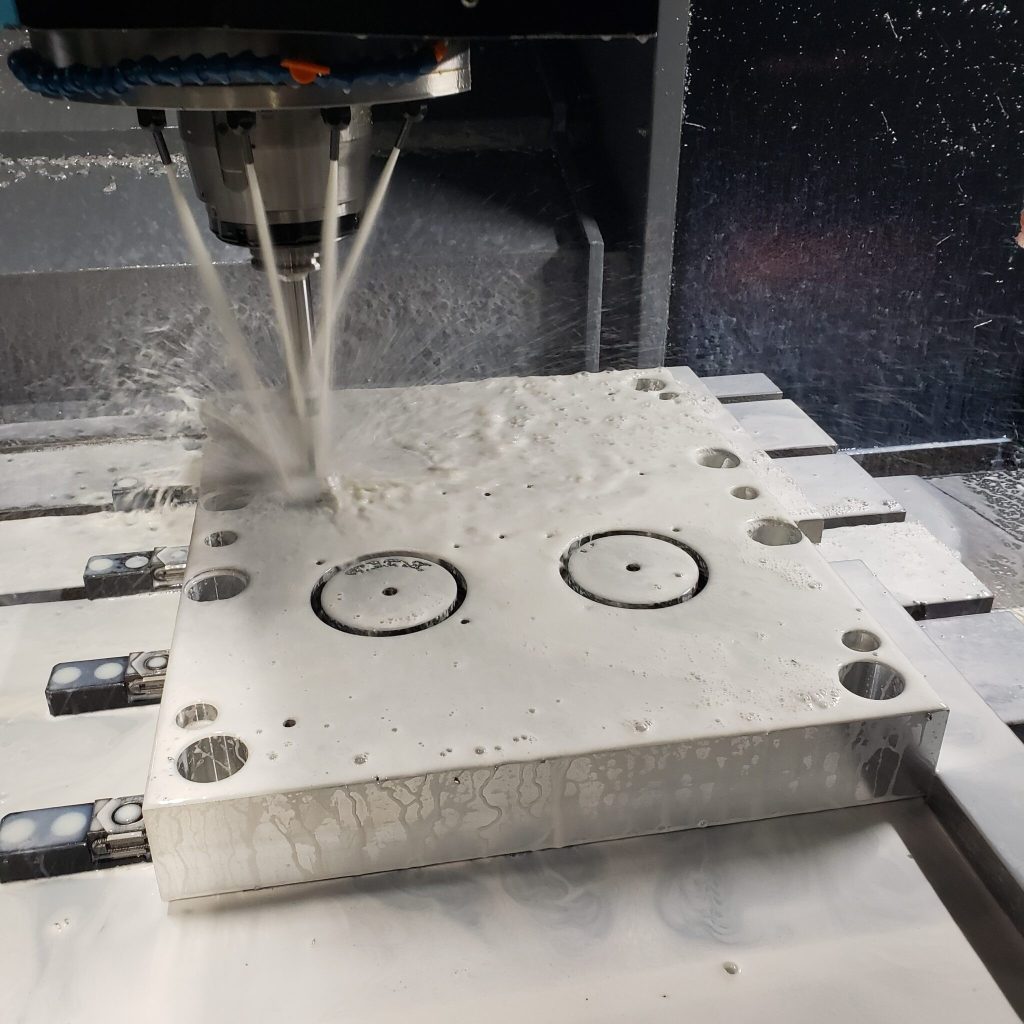

After the completion of the design for a custom plastic part, the initial phase in the production of custom molded parts involves the creation of a plastic injection mold. MXY utilizes a combination of skilled mold designers, advanced software technology, and high-end CNC machinery to fabricate molds for plastic injection, which are essential for manufacturing top-notch molded plastic parts.

The mold represents not only the primary investment in your injection molding endeavor but also plays a crucial role in determining the quality of the final products. When seeking an injection molding partner in China, it is imperative to collaborate with a supplier that possesses in-house mold manufacturing capabilities. This ensures that you have a single point of contact for both the project timeline and the quality of your parts.

Our team of injection molding specialists is eager to assist you with your mold construction project, taking you one step closer to the production of your custom molded parts. If you are in need of an injection mold supplier, rest assured that we have the expertise to meet your requirements.

In-House Mold Builds

All molds for MXY customers are constructed within our facility. Our team of skilled designers and machinists operate in the mold build area, utilizing cutting-edge software and CNC machinery. Once customer part designs are confirmed and ready for production, our team will create durable plastic injection molds to ensure trouble-free manufacturing.

Molds For Plastic Injection

Superior plastic components are produced through the use of well-made injection molds. Investing in a mold for your unique parts can be significant, which is why we are committed to guiding you through the process and familiarizing you with the various types of molds for plastic injection. We will ensure that you are fully informed before making any investment. Here, we offer a comprehensive overview of the fundamental construction types of injection molds and the advantages associated with each.

Insert Molds

- Low cost

- Average lead times from 5 to 15 days

- Good for small parts

- Good for 1 cavity molds and small order quantities

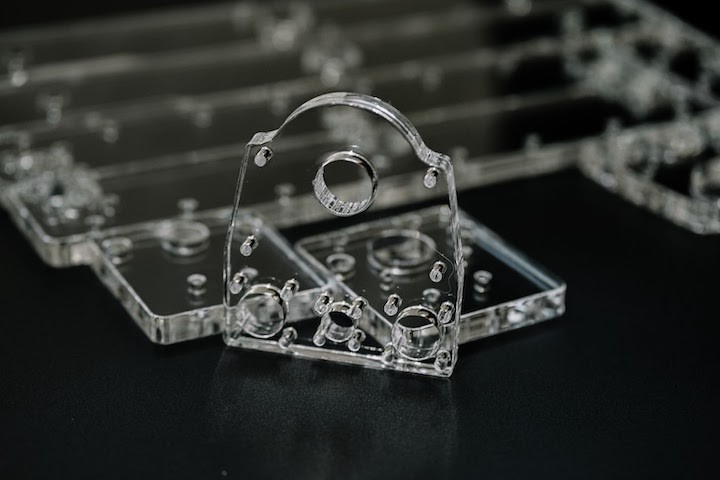

Insert molds consist of a cavity side and core side insert that are designed to fit within a custom mold base at MSI. This method allows us to provide customers with cost-effective tooling in a timely manner. The insert style design is particularly suitable for small to medium-sized parts that necessitate low quantity orders or quick part delivery. Despite their simplistic design, insert molds are crafted using top-notch materials and components, ensuring the production of high-quality, defect-free parts similar to those made with free-standing plastic injection molds.

Free Standing Molds

- Higher cost

- Average lead times of 3 to 8 weeks

- Best method for parts that will not fit into insert molds

- Best choice for multi-cavity molds to reduce part cost

Stand-alone molds, or free standing molds, are designed as a complete unit, including the mold base, inserts, and all necessary components for independent functionality. A well-designed stand-alone mold is suitable for production in any appropriately sized SPI standard injection molding machine. While stand-alone molds may come at a higher cost, they are ideal for multi-cavity production and large quantity orders.

Why Do Plastic Injection Molds Cost So Much?

People frequently inquire about the high cost of plastic injection molds. The reason behind this is that in order to produce top-notch plastic parts, a high-quality mold is essential. These molds are comprised of meticulously crafted components made from a variety of metals like aircraft grade aluminum or hardened mold steels. Skilled professionals known as “mold makers” are responsible for designing and creating these molds. These individuals have undergone extensive training in the mold making industry, spanning years if not decades. Moreover, mold makers require costly tools to carry out their work, including expensive software, CNC machinery, tooling, and precision fixtures. The time taken by mold makers to complete a plastic injection mold can vary from a few days to several weeks, depending on the complexity and size of the final product.

Advantages Of Molds Made In China

Manufacturing custom molded plastic parts in China ensures a consistent quality standard and reduces overall costs. The Modern China Plastic Injection Molding Company utilizes advanced equipment and offers dependable technical knowledge. By partnering with a trusted Chinese injection molding supplier, you can expect the use of top-notch materials, distinguishing them from other offshore suppliers. Opting for an injection molding specialist such as MSI Mold in China enables significant savings on shipping expenses and guarantees prompt customer service and communication. Stay engaged with our team of molding experts throughout the production process to ensure timely delivery of top-quality plastic parts.

Components of Injection Molds

A plastic injection mold is comprised of a set of metal plates, as well as complex machined parts on both the cavity-side and core-side of the mold. Each mold component is produced with precise tolerances, and the mold’s overall quality will have a direct impact on the quality of the parts produced and the mold’s longevity.