In today’s manufacturing industry,machining services CNC milling, CNC milling services are a crucial technology that provides precision processing solutions for various industries. Whether it’s prototype making or mass production,machining services CNC milling, CNC milling technology is known for its efficiency, accuracy, and reliability.

What is CNC milling?

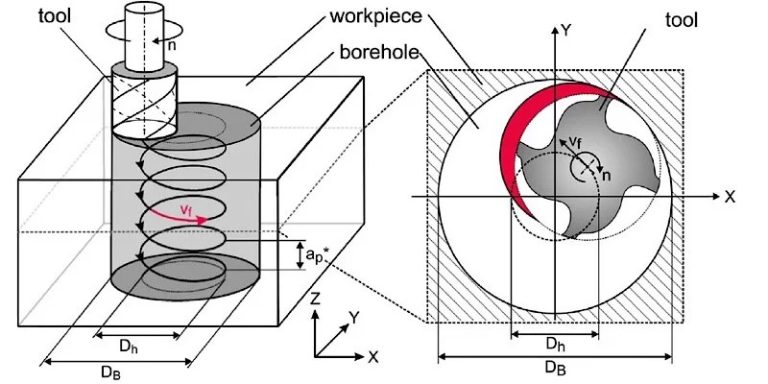

CNC milling is the process of performing milling operations using a machine tool controlled by a computer numerical control (CNC) system. Compared to traditional manual or semi-automatic milling,machining services CNC milling, CNC milling can achieve higher precision and repeatability, greatly shortening the processing cycle and improving production efficiency.

Main advantages

Precision and complexity: CNC milling can precisely control the movement trajectory and depth of the cutting tool,machining services CNC milling, enabling precise processing of complex parts such as internal structures and curved surfaces.

Batch production: Suitable for both mass production and customized production needs,machining services CNC milling, programming can quickly adjust processing parameters to meet different production requirements.Cost-effectiveness: Although the equipment investment and programming costs are higher,machining services CNC milling, in mass production, CNC milling is usually more economical and efficient than traditional processing methods, reducing human error and waste rates.

Application areas

CNC milling services are widely used in various industries, including but not limited to:Aerospace industry: Processing aircraft components,machining services CNC milling, engine parts, and other complex structures. Automotive Industry: Producing engine parts and brake systems for cars.Medical Equipment Industry: Manufacturing precision medical equipment parts, such as implants and surgical tools.Electronics Industry: Producing cases and internal structural parts for electronic products.

CNC milling services are not just a technical skill,machining services CNC milling, but an essential part of modern manufacturing. As technology advances and demand grows, it will continue to play a vital role in providing customized, high-efficiency, and high-precision processing solutions for various industries. Whether you are a small business or a large manufacturer, you can leverage CNC milling services to enhance your product innovation and boost your competitiveness in the market.

Factories play a key role in CNC milling services and are able to provide customers with a wide range of support and advantages:

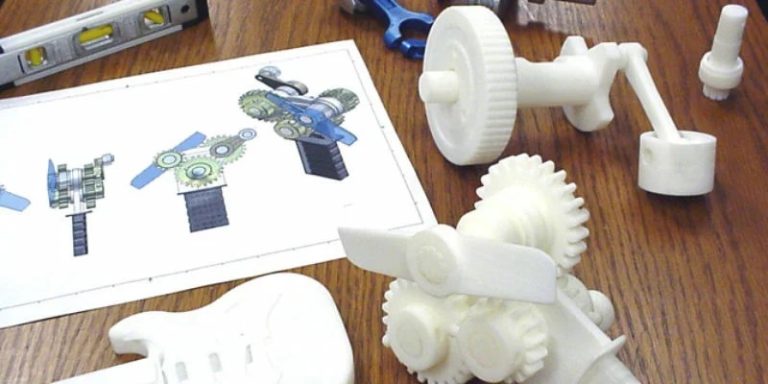

Professional technology and equipment: The factory has advanced CNC milling equipment and experienced technicians,machining services CNC milling, able to handle a variety of complex and precise machining needs. These devices can not only achieve high-precision processing, but also meet the processing challenges of various materials, such as metal alloys, plastics, composite materials, etc.

Customized solutions: The factory can provide customized CNC milling services according to the specific needs and design requirements of customers. Whether it is small batch production or large-scale production,machining services CNC milling, the factory is able to flexibly adjust according to customer requirements, ensuring the production of high-quality parts and products.

Cost-effectiveness and productivity: With CNC milling technology,machining services CNC milling, factories can achieve efficient production processes. Compared to traditional manual or semi-automatic machining, CNC milling can not only reduce processing cycles, but also reduce human error and scrap rates, thereby improving overall production efficiency and cost effectiveness.

Quality control and assurance: The factory usually has a strict quality control process and inspection standards to ensure that each batch of products can meet the quality requirements and standards of customers. Through the precision measurement and inspection equipment,machining services CNC milling, the factory can carry out a comprehensive inspection and verification of the processed parts to ensure the quality and reliability of the products.

Technical Support and service: In addition to CNC milling services, factories usually provide technical support and after-sales service. Customers can consult the factory technicians during the product design stage to obtain professional advice and opinions to ensure the manufacturability of the design and the best processing results.

To sum up,machining services CNC milling,machining services CNC milling, the factory plays a key role in CNC milling services, through its expertise, efficient equipment and comprehensive service capabilities, to provide customers with customized, high-quality and cost-effective processing solutions to help customers achieve market competitiveness and sustainable development of products.