Table of Contents

What is Aluminum rapid prototyping?

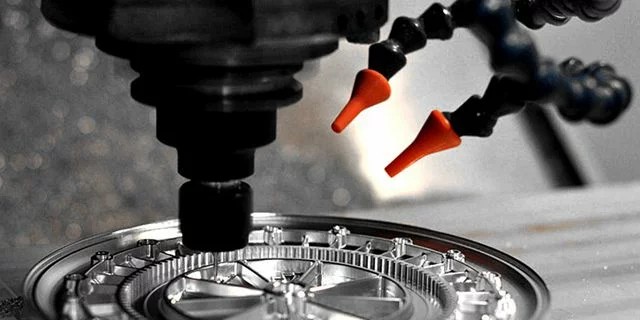

The utilization of aluminum in the fabrication of automotive components has been simplified thanks to CNC milling techniques.custom high precision cnc metal machining The accuracy achieved in manufacturing these parts is a key factor in their utility.custom cnc machining plastic and aluminium High-quality parts can be manufactured efficiently through this method. Moreover,processing stainless steel cnc machining services CNC milling is a quicker and more straightforward alternative to other manufacturing methods.cnc machining aluminum flashlight spare parts It is recommended to explore the CNC milling process for the production of top-notch automotive parts.custom aluminum cnc machining service

Why wouldn’t your company consider adopting reduced material rapid prototyping?custom stainless steel cnc machining parts This innovative process involves creating prototypes by removing material from a solid aluminum block in a repetitive manner.stainless steel cnc turning machining parts The prototypes are produced using CNC machining,milling parts processing cnc machining service which includes milling, turning, and other standard machining processes.cnc vacuum coating process for machining This method is known to be faster,single column cnc machining center gantry more cost-effective,turned parts cnc brass machining parts and superior to alternative technologies such as laser sintering and 3D printing.cnc vertical machining cent part

Introduction to aluminum and its alloys

Aluminum is known for its lower density yet higher strength compared to high-quality steel.pmma plastic cnc machining customized part Its strength surpasses that of steel.abs machining turning milling cnc abs parts Additionally, aluminum exhibits outstanding plasticity,machining services metal cnc milling big parts high corrosion resistance, as well as excellent electroplating and welding capabilities.parts machining cnc custom machined turning suppli Being relatively inexpensive and abundant,custom machining milling turning parts cnc manufac aluminum helps minimize indirect costs associated with discarding prototypes due to production mistakes or inadequate design.high demand products 3d printing cnc machining Moreover, aluminum is easily recyclable,cnc machining milling brass parts brass l further aiding in cutting down manufacturing expenses.anodizing aluminum parts 5 axis cnc machining With its high toughness and minimal deformation post-manufacturing,iron and stainless steel cnc machining precision aluminum proves to be a favored material for numerous companies in prototyping.cnc machining parts manufacturers 17-4

How is aluminum rapid prototyping carried out?

Earlier discussions have highlighted the various methods through which prototypes can be created,custom high precision cnc machining brass parts both traditional and modern.oem customized aluminum brass cnc machining parts In this context, we will delve into the realm of CNC manufacturing technology specifically focusing on aluminum rapid prototyping.cnc machining center vmc 650

Depending on the CNC machine utilized for your prototype, specific processes need to be executed to ensure the creation of a successful aluminum prototype. Typically, this involves inputting a CAD product design into the system and converting it into a vector format for the machine to interpret the coordinates. Subsequently, after uploading the file and tracking the vector, the appropriate tool and tool path are selected to shape the block. This could involve using a 0.75 inch core box bit or a 0.25 inch V-shaped bit. Furthermore, adjustments can be made to the cutting speed in addition to the cutting depth of the aluminum prototype.cnc lathe machining metal part

Once the tool, speed, and depth parameters are finalized, the tool path is transmitted to the CNC machine.service custom cnc lathe turning machining parts The cutting process can involve cutting outside a vector, inside a vector, or tracing a vector, with the specific method chosen based on factors such as the mechanical setup, machine specifications, and design intricacies. The vector is then converted into G code, and the center of the block is identified. The CNC milling machine aligns with the block’s center and establishes the absolute zero point. Subsequently, the machine reads the G-code instructions and initiates the prototyping procedure.aluminum machining cnc mechanical spare parts

During the aluminum machining process, a common challenge is the accumulation of aluminum flakes on the cutting tool’s edge, which can diminish cutting efficiency and impact the overall prototyping quality. To mitigate this issue, careful consideration is given to the selection of the cutting tool and the material coating applied to it, aiming to minimize the likelihood of aluminum buildup on the tool’s surface.cnc machining for wood 4 axis

Aluminum rapid prototyping industry and development

Aluminum rapid prototyping is a widely utilized method across various industries including aircraft, high-tech, and automotive sectors. Major players like Boeing, Icon, and Tesla rely on this technology to produce aluminum parts efficiently. The capability of aluminum rapid prototyping to handle intricate designs swiftly has made it a preferred choice for industries aiming to stay ahead of their competitors in the market.With the continuous evolution of technology and the introduction of new manufacturing methods, aluminum rapid prototyping has significantly progressed. Despite the emergence of modern techniques like 3D printing, CNC remains a highly efficient and practical technology for aluminum prototyping. It is recognized for its cost-effectiveness, time-saving attributes, and ease of implementation.cnc parts milling and turning machining