Table of Contents

CNC machining

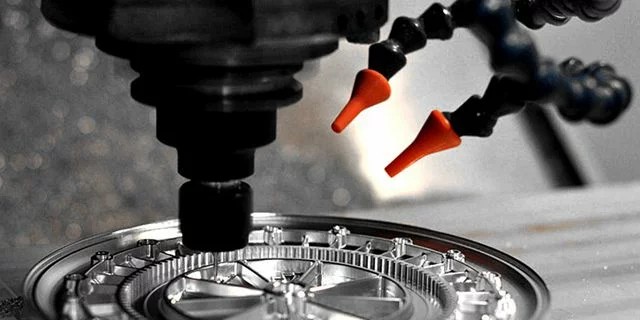

Based on the aforementioned illustrations, it is evident that individuals have gradually started embracing the real world. Are you familiar with the manufacturing process of auto parts? Interestingly, car components such as car limbs, the front of the vehicle, and even small parts can undergo CNC machining before being painted.bushing machining cnc

CNC is a machine that operates automatically through a program. It utilizes computer-aided design, aided manufacturing, digital control, and other advanced technologies to create a three-dimensional model on the computer. This model is then used to cut and excavate a piece of material on the machine tool of the machining center.cnc machining bezel

Once the workpiece is installed, the CNC system takes over and controls the machine tool. It automatically selects and changes the tool based on different processes, adjusts the spindle speed, feed rate, tool track, and other auxiliary functions of the tool spindle. This allows for the successive completion of multiple workpieces without the need for manual intervention.custom cnc machining racing

In multi-process processing, the entire process is controlled by the program and is not influenced by the operator.glock parts cnc machining

- When processing in CNC lathe, it is important to guarantee the accuracy and surface roughness of the workpiece.

- The processing route should be minimized, idle time reduced, and processing efficiency improved.

- It is advisable to simplify numerical calculations and processing procedures as much as possible.

- Utilize subroutines for reused programs.

The Transformers in the movies are coming to life

Transformers

Numerous individuals have likely viewed the popular film (Transformers) and been captivated by their impressive and attractive appearance! Brimming with strength and energy, they stir the excitement in people. cnc precision machining These Transformers have sparked creativity and curiosity in the realm of science fiction. Naturally, actual Transformers do not exist in reality.cnc aluminium machining

powerful robots

Nevertheless, due to the ongoing advancements in high technology, powerful robots are no more just characters in science fiction films. These robots, blending immense strength with cutting-edge technology, are now a part of everyday reality for people.cnc machining gun parts

Japanese company creates realistic Transformers

Transformers, a beloved animated series among teenagers, copper cnc machining has successfully made its way onto the silver screen thanks to Hollywood’s adaptation. As a result, it is not uncommon to find autobot toys in the homes of most teenagers today.cnc machining parts formal

During a span of three years, a Japanese company dedicated its efforts to developing functional cars that could transform into rideable robots of varying sizes. curvic coupling cnc machining Despite encountering minor technical obstacles along the way, the project persevered and ultimately came to fruition.cnc spare part machining

Known as J-deite Ride, this peculiar machine stands at an impressive height of 4 meters and possesses the ability to morph into different forms. Asratec Corp., a robotics software company owned by SoftBank Group Corp., spearheaded the development of this remarkable creation.carbon graphite cnc machining

With a total of 49 joints and a frame primarily composed of aluminum alloy, the robot offers the unique feature of accommodating passengers in both its modes. Inside the robot, there is a cab where individuals can sit comfortably. Whether manually operated from the cockpit or controlled wirelessly or wired from outside, the robot provides a range of options for its operation.cnc 3 axis vertical machining

The length of the car measures 4 meters, while its height is 1.4 meters, providing enough space for two individuals. The robot gracefully retracted its hands and head, then proceeded to lift its legs, adjusting its weight as it settled into the driver’s seat. Remarkably, within a mere minute, it can metamorphose into a humanoid robot towering at a height of 3.7 meters and a width of 4.2 meters. Returning to its car form is equally effortless. The car boasts a theoretical speed of 60 kilometers per hour, while the humanoid robot can walk at a speed of 30 kilometers per hour, conveniently controlled via wireless remote. Primarily designed for amusement parks, this car serves as a source of entertainment. Although the robot cannot save the world like its animated counterparts in movies and TV series, this project serves as a catalyst for people’s imagination and sets a precedent for future technological advancements.used cnc machining doosan puma

Interestingly, did you know that all the components of this transformer can be manufactured using CNC milling services? Let’s delve into the intriguing connection between CNC milling services and the renowned Chinese “Transformers.”cnc machining center 3 axis

Chinese father makes Transformers

In Xi ‘an, China, the father of a child made “Transformers” armor for his son.vertical machining center cnc 15000rpm

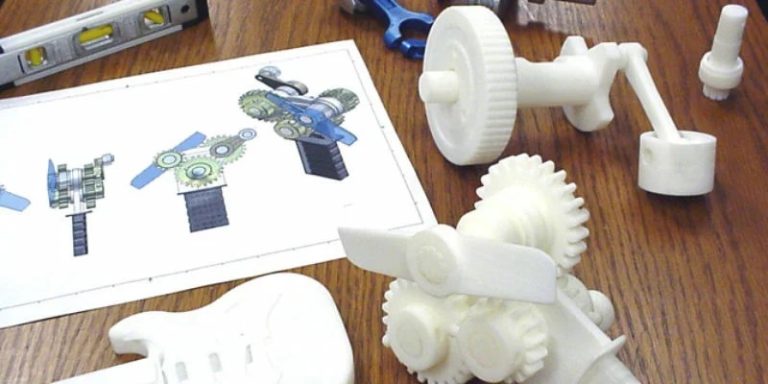

Indeed, China boasts numerous CNC machining factories. Once armed with the necessary drawings and ideas, these factories will diligently cater to your specifications and fabricate a comprehensive Transformer. Through the process of crafting individual components and subsequently assembling them, a fully functional transformer is brought to life.cnc machining service atm pinpad cover atm keypad 3d

CNC machinery factories

In China, a man from Henan, who works as a farmer, is known for creating Transformers. His interest in making Transformers sparked after watching the movie, and he decided to embark on the challenging journey of crafting them himself. Despite facing obstacles such as the extensive time and effort required, along with the need for various materials and precise CNC milling calculations, dimensions, and structural considerations, he remained determined. Throughout the process, his wife urged him to abandon his ambitious project, leading to numerous arguments between them. Nevertheless, he remained steadfast in his goal of completing the production of Transformers within a year.part cnc machining

In China, numerous CNC machinery factories exist that have the capability to produce Transformers. These factories are able to create products based on customers’ specific size, design, and material preferences.cnc machining ningbo

What are the advantages of CNC?

1) The existing RP technology cannot match the unmatched size control provided by high dimensional stability, high machining accuracy, and high repetition accuracy.

2) The CNC universal milling machine offers a wide range of material options, including almost all engineering plastics and metal materials, ensuring consistency between prototypes and mass production materials.cnc machining metal parts

3) CNC machine parts exhibit a high surface finish that can rival or even surpass that of open mold products after undergoing grinding, polishing, and surface treatment.cnc precision automatic lathe machining

4) With the ability to operate continuously for 24 hours, CNC machine tools deliver high processing efficiency.cnc machining heater copper parts

5) When it comes to processing small batch or large size parts, CNC technology proves to be more cost-effective compared to RP technology.cnc vertical machining center trade

What are the disadvantages of CNC?

1) Exceptional dimensional stability, precise machining accuracy, and consistent repetition accuracy are achieved. The size control surpasses that of current RP technology.

2) A wide array of materials, including nearly all engineering plastics and metal materials, can be utilized in CNC universal milling machines to ensure uniformity between prototypes and mass production materials.component metal machining parts cnc aluminium

3) CNC machine parts exhibit a superior surface finish. Through grinding, polishing, and surface treatment, the production quality can match or even exceed that of products made from open molds.cnc machining center 3 axis hidenhain

4) CNC machine tools are capable of continuous operation for 24 hours, resulting in high processing efficiency.craphite machining cnc

5) Processing small batch or large size parts is more cost-effective when compared to RP technology.cnc machining components

Background of Chinese handboard industry

The handplate model industry is emerging as a key player in the market due to the intense competition in the social market and the growth of the industrial design sector in China. Hand plate enterprises are not only focusing on industrial design but also on the production of product models. The quality and effectiveness of product development require verification through hand models. As a result, the handplate model industry is evolving into a distinct and thriving sector, separate from the industrial design process. Numerous professional hand model companies have surfaced, with larger enterprises and industrial design firms establishing their own hand model departments.cnc machining works

The master model industry is poised to become a sunrise industry in the future, given its current development status and advantages. One major advantage is the high social demand for hand models, driven by increased investment in product research and development by companies. This demand is also indirectly influenced by the overall growth of the domestic social economy.