There exist approximately 10 primary rapid prototyping methods, depending on how they are combined.cnc machining turning parts cnc milling machining Which one would be most suitable for your medical device design?cnc machining part/custom aluminum cnc machining s Alternatively, you may have developed a product for a car, aircraft, or household appliance. Each industry and product type has specific requirements for prototypes. aluminum-cnc-machining-part You must have some thoughts on this matter, correct?custom cnc machined parts cnc oem machining part Is the purpose solely to demonstrate to investors that it has an appealing appearance? Or perhaps you wish to verify its functionality so you can skip the final touches and opt for a more cost-effective approach, or maybe you intend to conduct tests. You might subject the prototype to impact and pressure, expose it to heat, or immerse it in water.kunshan cnc machining

Every product and its respective use is equipped with the most advanced technology to develop its prototype. However, if I were to delve into a comprehensive analysis of all the methods in an article, it would consume a significant amount of time, which is not feasible at present. Hence, we will focus on two prominent technologies that collectively dominate approximately 30% of the prototyping market: SLA prototyping and SLS prototyping of plastics. cnc titanium machining Consequently, let us now proceed with the comparison between SLA 3D printing and SLS 3D printing.cnc machining bike parts

SLA printing development

There are two main methods for printing SLA: direct SLAs and reverse SLAs.cnc machining service china

The direct method involves a liquid polymer tank and a base plate with a curing layer below the polymer surface.oem cnc machining A UV laser follows the current cross section of the part, solidifying the first layer. The base plate then moves down one layer, and a knife ensures the polymer fills the area above the plate before solidifying the next layer.brass cnc machining services

In contrast, the reverse method involves a transparent substrate positioned upside down. The laser solidifies the polymer through the plate, which then rises. This process can be likened to slowly lifting an object out of water, with the difference being that the object is initially submerged in the water. Through SLA printing, objects can be created layer by layer using liquid polymer.cnc machining parts 4140

SLA printing Technology

There are two distinct approaches to printing SLA, known as direct SLAs and reverse SLAs.cnc 4 axis machining

The direct flow method is the original technique for SLA printing. In this method, the printer consists of a liquid polymer tank and a base plate with a curing layer positioned below the polymer surface. A UV laser follows the current cross section of the part (the program divides the part into layers and generates a laser path for each slice), resulting in the formation of the first hardened layer. cnc machining brass The base plate then lowers by one layer, and a specialized knife moves across the slot’s surface to ensure complete polymer filling above the plate. The subsequent layer is then solidified.cnc machining turning part

On the other hand, the reverse method differs in terms of part orientation and movement. In this approach, the substrate is transparent and positioned upside down compared to the direct method. The laser solidifies the polymer through the plate, which then rises instead of descending. This process can be likened to gradually lifting an object out of water, with the distinction that in the latter process, the object is initially submerged in water. With SLA printing, you have the ability to create objects while they are immersed in the liquid within the container.cnc machining aluminum dropshipping

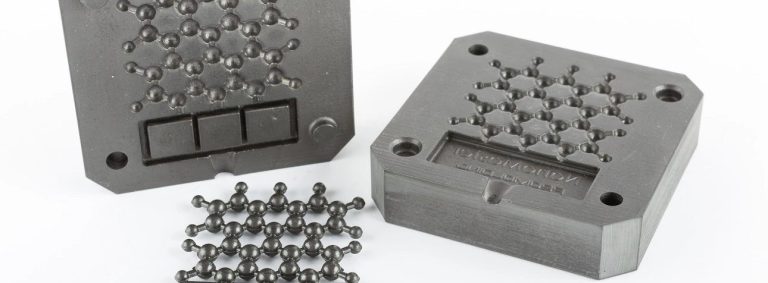

Description and history of SLS

SLS, a 3D printing process, was pioneered by Texas professor Carl Deckard with the aim of reducing the number of castings required for mass production. Subsequently, Deckard sold the patents to 3D Systems. The company successfully implemented SLS with metal powders, leading to a significant revolution in metal parts manufacturing. Presently, this technology stands as the most widely utilized method for printing metal parts. However, during its development, it was discovered that the powder used in SLS posed potential hazards. The powder is extremely delicate and can be easily inhaled. Consequently, unlike SLA, the SLS technology is not suitable for desktop enthusiasts.cnc vertical machining center price

In this process, plastic powder serves as the primary material. The powder is spread on the bottom plate using a specialized knife. Similar to SLA, the laser traces the cross section of the part. Subsequently, the base plate is lowered by one layer, and the powder is spread once again. As you can see, this process bears a striking resemblance to SLA, wouldn’t you agree?pp polypropylene cnc machining service

SLA. This process uses polymers that become harder under ultraviolet light, or so-called photopolymers. There are many different resin compositions, so most of them are differentiated by use:

Standard resin is the most cost-effective option with lower mechanical properties, yet it offers high quality comparable to injection molding. Some variants are transparent, allowing for clear prototypes like car lights.cnc metal machining powder coating

Engineering resin, on the other hand, is suitable for functional prototypes in various forms such as ABS-like, heat-resistant, rigid, or flexible. Despite the versatility, they still provide a good surface finish and improved strength.cnc vertical machining center xh7126

Resin designed for medical purposes includes biocompatible polymers suitable for prolonged contact with human tissue. This feature, found in some Class I and Class II photopolymers used in SLA printing, offers a significant advantage.5 axis cnc metal machining

SLS. The technique was originally used for nylon. Over time, some other materials have adapted to the technology.custom cnc machining parts components

Nylon is the most commonly utilized plastic in SLS due to its superior durability, heat resistance, and toughness compared to all SLA materials.cnc timing belts reworking and machining

Polyurethane is a flexible plastic that is perfect for creating basic polymer parts through casting.

Wax is an excellent material for casting models, as you can easily coat the model with a molding mixture and heat it until it liquefies.machining service medical auto cnc parts

SLA printing has a significant downside due to the excessive support material used, which requires a cutting process to eliminate. Moreover, the removal of support remnants in the cut-off region adds to the time-consuming nature of the entire procedure.printing machine parts cnc machining service

In contrast, the curing of the part in SLA printing is not entirely complete, with some areas between layers only partially reacting. Utilizing UV chambers to enhance the strength of printed parts is beneficial, although not mandatory.custom metal cnc machining milling turning oem

On the other hand, the surface finish of SLS parts is typically inferior to that of SLA parts. Therefore, additional sanding and mechanical post-treatment are often necessary to achieve a satisfactory surface finish, resulting in a considerable amount of time being spent.aluminum anodizing snus can box cnc machining

Conclusion: What to use when?

In general, the manufacturing process yields high-quality components, although it is considerably more costly compared to SLS. If SLA is directly employed, the liquid plastic remaining in the tank cannot be recycled and has a short lifespan, making it preferable to keep the printer loaded. Additionally, the process necessitates the removal of support structures. However, one advantage is the wide range of materials that can be utilized.turning parts custom metal cnc machining services

SLA is recommended for medical devices, transparent parts with a smooth surface finish, as well as specific injection or cast models. It is an ideal choice for showcasing your product, as the resulting parts are of exceptional quality.oem precision cnc machining parts aluminum milling

On the other hand, SLS offers superior strength and performance compared to SLAs. However, its surface finish is significantly inferior (approximately 2-3 grades lower). This manufacturing process is much more cost-effective than SLA. Furthermore, there is no need for a support structure since the previous layer of powder supports the subsequent layers, and any leftover powder can be reused.4 axis cnc curved wood legs machining lathe-millin

If the component needs to withstand higher loads, corrosion, or vibrations, SLS is the recommended option. SLS is suitable when surface finish is not a critical factor and the budget is limited. It can be utilized for personal purposes or testing.cnc machining set precision cnc machining stainles