Table of Contents

Automotive Lighting Prototype Manufacturing

the primary technologies

Currently, the primary technologies utilized in automotive lighting prototypes consist of 3D printing, CNC machining, silicone molds, and rapid aluminum molds, each offering unique benefits.high precis cnc machining accessories The following are different technical applications at different stages of development based on Vick’s years of experience in providing rapid prototyping services and automotive prototyping for the design and development of automotive lamps:

Concept and engineering stage: CNC machining

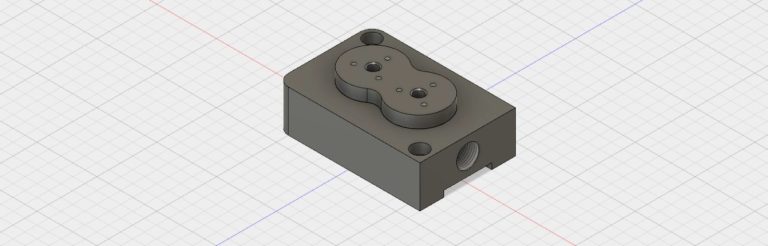

CNC headlamp

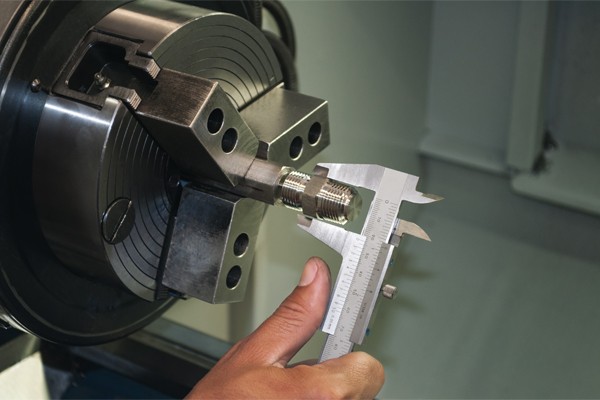

The CNC headlamp prototype machining process is known for its high precision, quick response time, and short lead time of 1-2 weeks. This enables the production of intricate shapes from a single material piece. Typically, during the conceptual and engineering design phases, specific components of the headlamp, like the light tube or reflective cup, must be fabricated for visual or functional evaluation. This necessity often calls for the creation of precise prototypes using actual materials within a short timeframe, making CNC machining the optimal solution for auto parts and accessories. CNC milling services are commonly utilized for this purpose.Due to the complex structure of the lamp, there are many optical details and backdowns, even high-precision 5-axis CNC can not be machined the entire part at once. CNC programming engineers possess extensive expertise in the production of prototype lamps and are required to assess the viability of the manufacturing process upon receiving the lamp design drawings. They specialize in providing machining services for these specific components. that cannot be machined as a whole, solutions need to be provided for dismantling, especially for critical surfaces.cnc machining stainless.In the later stage of the production of the hand board, the manual post-processing work such as deburring, polishing, gluing and painting is particularly important and will directly determine the final appearance.cnc machining motorcycle accessories

Low volume testing stage: Silicon casting

Silicone molds do not require the creation of a drawing mold, making them one of the most straightforward methods for producing quick tools. They offer good flexibility and replication performance, especially when used for CNC machining aluminum parts. As a result, this technology is commonly utilized in the small-scale production of automotive lamps, as well as CNC wood machining. It is crucial to carefully select the manufacturing methods and materials when producing small batch headlamp parts with silicon molds to ensure that the appearance and performance requirements of each part are met.

For LENS and BEZEL that require mirror finish, we usually choose CNC to make PMMA prototypes with high quality surface finish. The silicone mold made by this method can ensure the perfect appearance of the casting.cnc machining for sale

We employ RP technology, specifically SLA, to fabricate prototypes for structural components like shells that have minimal aesthetic demands. In order to ensure superior temperature resistance, we opt for AXSON PX223 as the casting material. Additionally, we offer 5-axis CNC milling machining services.

There are headlights, taillights, fog lights and so on.aluminium cnc machining parts All kinds of lights have different uses. oem cnc parts centering machine machining cnc If you are an automotive lighting manufacturer, aluminum cnc machining part have you conducted research on the effects of headlights?turning cnc machining parts Do you understand the prototyping process in the design stage of the car lights?cnc machining service

Design requirements for automotive lighting

Headlight

Car headlights, also known as car headlights, as the eyes of the car, not only related to the external image of the owner, but also related to the safe driving at night or in bad weather conditions. cnc machining for metal The material of the headlight needs to ensure that the vehicle has bright and stable lighting when driving at night, so that the driver can clearly identify the object within 100 meters. At the same time, it is essential to incorporate an anti-glare mechanism to guarantee the security of nocturnal driving in the realm of CNC vertical machining.

Taillamp

Taillights play a crucial role in conveying vital information, including braking and steering signals. The frequent utilization of these signal lights in urban areas has led to their significance. Additionally, 3D printing machine parts and CNC machining services contribute to their efficient functioning, the performance requirements for materials are also high. cnc machining titanium fuel filter The material must have high heat resistance, good workability, wettability and bright color.cnc machining parts

Materials and performance requirements:

Fog lamp

In the case of low visibility, such as rain and fog, the role of headlights is limited. stainless cnc machining Therefore, fog lights need to pass through obstacles such as fog to ensure normal sight. CNC machining services for parts are essential for producing components with precision and accuracy. In order to withstand the intense power and heat generated by fog lamps, the material used must possess exceptional heat resistance capabilities, the required material should also have a high heat resistance.custom cnc machining

Materials and performance requirements:

Rapid mold materials

Rapid mold materials are mainly mild steel (e.g., P-20) and aluminum (e.g., 7075 T-6 aerospace grade aluminum). In contrast to solid steel, the processing speed can be enhanced by 15% to 30%, the time required for polishing can be expedited by 3 to 10 times, and the weight is comparatively lighter, thus reducing the mold production cost and shortening the cycle. Furthermore, rapid aluminum tools aid in temperature regulation, leading to quicker cycle times and the reduction of plastic strain in wood CNC machining. As the vehicle is still in the developmental phase, it is crucial to assess both its processing cycle and production expenses, which can be determined with the help of fast aluminum molds. For example, engineers can produce small batches of lights with rapid aluminum tools for load testing or pre-market release. The primary benefit of rapid aluminum molds lies in their utilization of authentic materials and structures. Not only the reaction cycle is fast, but also the production cycle and cost can be reasonably and truly evaluated. The following is the Vic fast taillight aluminum production project cycle:Compared with ordinary steel molds, the surface quality made of these two materials is almost the same. The lifespan of the aluminum mold is determined by the intricacy of the product, and despite being significantly shorter than that of the steel mold, it can also achieve a service life of not less than 1000 times, which is more than enough for the initial loading test.5 axis cnc machining parts service.The following are aluminum tool stands on taillight components: