After finalizing the concept for your product,cnc machining auto spare parts the next step is to select the appropriate materials and manufacturing processes for each component.machining services cnc vacume casting3446 Recent trends show a growing preference among manufacturers for utilizing aluminum alloys in the production of metal prototypes.stainless steel cnc machining solutions The benefits of these alloys are clear,machining centre & partsmachin cnc stok and there are various advanced techniques available for aluminum manufacturing.stainless steel cnc machining service coating Below are some compelling reasons to opt for aluminum machining when prototyping.cnc machining center 5 axis

Excellent machining performance

Machinability is a crucial factor that defines the efficiency of machining a specific metal.custom cnc machining plastic injection molding It is determined by dividing the current material processing speed by the sample material processing speed,printing parts services cnc lathe machining with the sample typically being a simple carbon steel.machining turning custom cnc brass part For instance, when comparing the processing speed of aluminum alloy to that of 1212 steel,precision aluminum alloy cnc machining milling we find a ratio of 360%, indicating that aluminum can be cut 3.6 times faster than steel.cnc vertical machining 1000 5 axis While steel may offer greater strength and durability,ip68 waterproof cnc machining aluminum case in prototyping, the speed of processing takes precedence.stamping parts cnc milling turning machining Sacrificing some longevity for quicker sample production is often a necessary trade-off.plastic cnc machining customized part

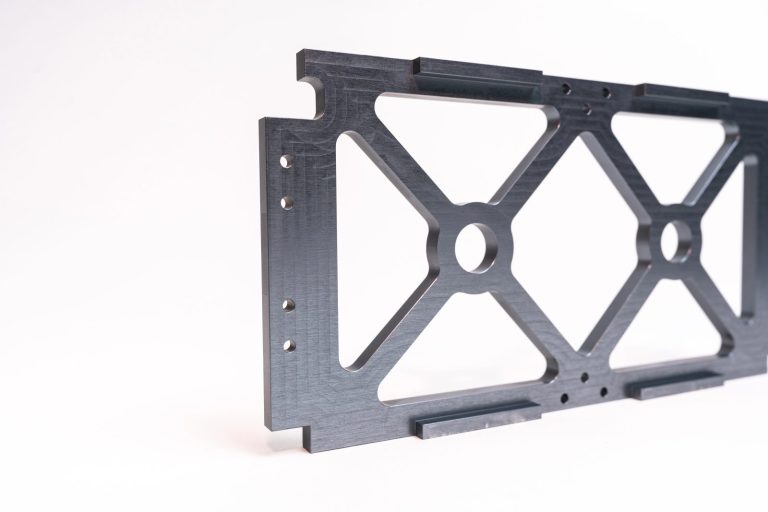

Aluminum alloys are capable of undergoing processing through a range of techniques.cnc vertical machining 800mm x 600mm Due to their electrical conductivity, numerous electrochemical and coating possibilities are accessible as well. Among the commonly utilized methods in aluminum processing firms are CNC turning, CNC milling, grinding, polishing, honing, drilling and tapping, electric discharge machining (EDM), electrochemical machining, grooving, and more. Through the integration of different technologies, components of nearly any level of complexity and accuracy can be achieved.cnc laser machining for sale

High precision and surface finish

CNC aluminum, also known as custom aluminum manufacturing,cnc 5 axis machining center wood relies on CNC machining.cnc vertical machining center rb212 dv1422 Unlike thermal processes, it does not require melting and continuous solidification,mechanical products metal cnc machining service thus avoiding the inherent deformation.cnc turning machining service custom precision CNC machining is renowned for its ability to achieve exceptional surface finish and tolerances. By applying some polishing techniques, it is even possible to obtain a mirror-like surface. The maximum allowable tolerance for aluminum machining is IT8-7, while the surface finish is measured at RA 1.25 mcm.cnc laser cutting machining service

Easy to cast and form

Aluminum alloys exhibit superior casting characteristics.cnc vertical machining 5 axis milling With a master model of the part, sand-cast parts can be readily obtained for small batch manufacturing needs. Although the contraction is minimal, the fluidity is exceptional. This ensures that the metal can fill even the tiniest intricacies, while the shrinkage effect from solidification does not result in significant flaws in the part. Consequently, material waste can be significantly minimized across 10 or more batches.Aluminum billets can be processed using molding as an alternative method. Due to its high malleability, aluminum can be heated and shaped by hammering it into the desired form. Although thermoforming is commonly linked to mass production through die casting nowadays, there are adaptable tools and equipment that enable blacksmiths to alter the shape of the blank without requiring specific molds. An advantageous aspect is that molded blanks possess greater strength compared to regular blanks.cnc machining metal customized parts

Corrosion resistance

Aluminum producers benefit from the corrosion resistance of their alloys.china wholesale cheap cnc machining service When faced with orders that prioritize corrosion prevention, they can simply opt for aluminum without any concerns. The metal naturally develops a thin oxide layer on its surface, providing a protective barrier that shields it from harmful external elements. There is no necessity for additional coatings or paints to prevent rusting. Applying a coating or paint will further enhance the part’s resistance to external corrosion.cnc machining deburrs 1 piece

Excellent weight to strength ratio

Aluminum alloys possess a weight that is three times less than steel, making them a popular choice in the aerospace sector. Despite their lightweight nature, numerous alloys have been enhanced to ensure that aluminum can match the strength of steel. Therefore, if you are contemplating the creation of an object where weight plays a crucial role, such as a handheld device or an aircraft, it is advisable to opt for an aluminum alloy not only for the initial prototype but also for the final product.aluminum cnc service china machining

Medical use

Some aluminum alloys have the potential to be utilized in the medical field, although this fact is not widely recognized. Alloys such as 6063, 6061, and 3003 are known to be suitable for use with human tissue. In the realm of biocompatible metal components, medical manufacturers have few choices, making aluminum alloy a cost-effective alternative. On the other hand, titanium is another option to consider. Unlike aluminum, titanium alloys are difficult to machine, whereas aluminum is both efficient and easy to produce.cnc vertical machining center torna

Non-magnetic alloy

Aluminum alloys are non-reactive to magnets, which is generally insignificant unless magnetic field resistance is a crucial requirement for the device’s functionality. While there are other non-magnetic alloys available, aluminum stands out as a cost-effective and durable option. Opting for aluminum as a material for device housing or fixtures that need to remain non-magnetic is a practical and budget-friendly choice.cnc machining water pump impeller

Good electrical conductivity

Copper is extensively utilized for wiring and appliances due to its widespread availability. Nevertheless, copper possesses certain drawbacks such as its softness, high cost, and limited resistance to corrosion. On the other hand, aluminum addresses all of these limitations while maintaining comparable electrical conductivity to copper. Consequently, considering aluminum for the fabrication of prototypes in electrical devices could prove to be a feasible alternative, particularly when intricate electrodes need to be manufactured.cnc machining metal micro parts

Recycle option

Contemporary industry places emphasis on environmental conservation, sustainability, and reduction of air pollution. In recent times, the consideration of these aspects has gained significance in the choice of materials for products. Consequently, polymers and plastics are no longer the primary choice. Eliminating plastic components can be challenging, especially when they serve their intended purpose effectively. The recycling of industrial-grade plastics is frequently intricate and expensive. Simply incinerating or disposing of them in landfills is not an ideal solution. Hence, manufacturers seek alternative materials that are more eco-friendly.machining usinag jante cnc milling