Aluminum Alloy Die Casting

- A manufacturing process that produces accurately, defined, smooth and textured-surfaced metal parts

- Accomplished by forcing molten metals into a mold form due to high-pressure systems

- Corrosion resistant

- Highly conductive

- Have a good stiffness and strength-to-weight ratio

- Based on rapid production

- Allows a high volume of die casting parts to be produced fast

- Is more cost-effective than alternative casting processes

What is aluminum die casting?

Aluminum die casting alloys are known for their lightweight properties and high dimensional stability, especially when it comes to intricate part geometries and thin walls. In addition, aluminum offers excellent corrosion resistance, mechanical strength, and impressive thermal and electrical conductivity, making it a preferred choice for die casting applications. The low-density of aluminum metals plays a crucial role in the die casting industry. The Aluminum Die Casting process is designed to maintain durable strength even at extremely high temperatures, necessitating the use of cold chamber machines. During this process, the molten metal is contained in an open holding pot, which is then heated in a furnace until it reaches the required temperature. To prevent damage to the normal pumping system, the molten metal is ladled from the pot for each casting, as the high temperatures involved would be detrimental to the standard pumping mechanism. It is worth noting that the pressure requirements for cold chamber castings are typically higher compared to those of hot chamber die castings.

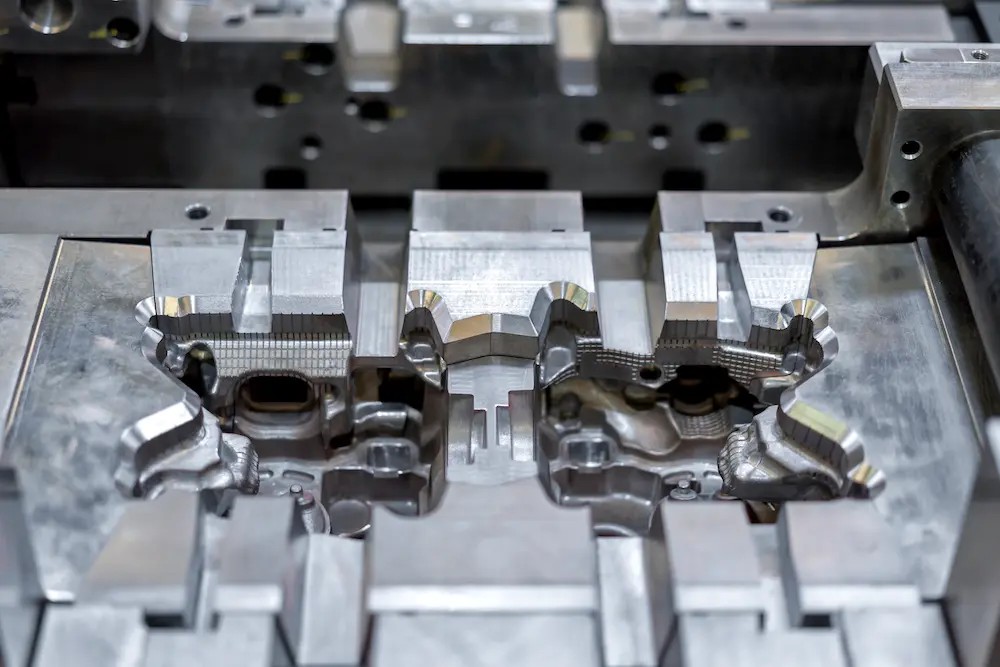

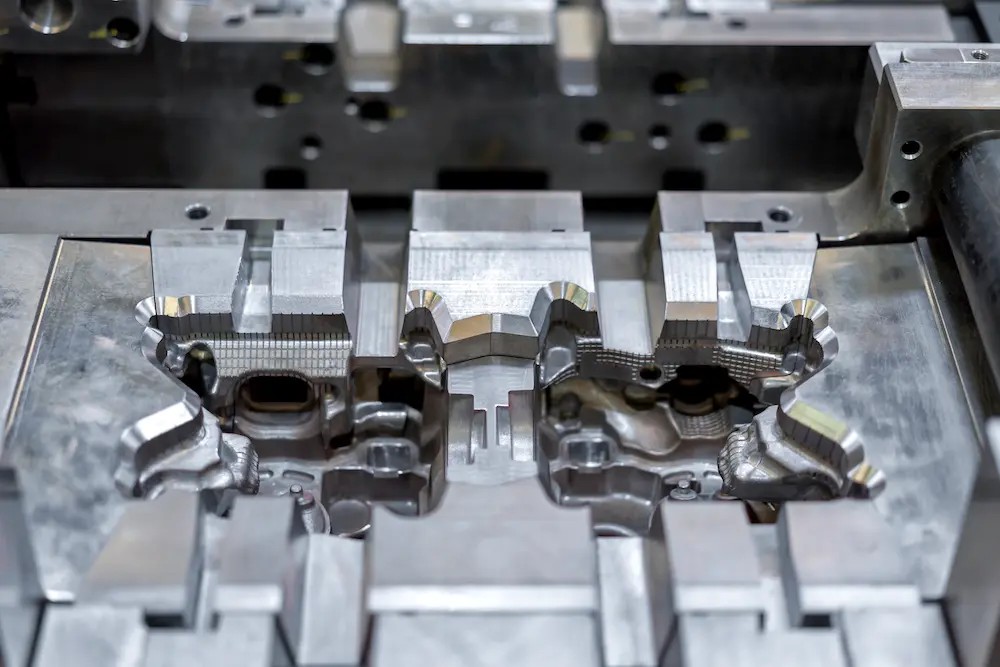

Aluminum die casting is a metal-forming technique that enables the production of intricate aluminum components. Aluminum alloy ingots are heated to extremely high temperatures until they completely liquefy. The molten aluminum is then injected into a steel die, or mold, at a high pressure. An example of such a mold for automotive parts can be seen above. The die consists of two halves, which are separated once the aluminum has solidified, revealing the cast aluminum part. The resulting aluminum product is accurately shaped with a smooth surface and often requires minimal or no additional machining processes. Since steel dies are utilized, the process can be repeated numerous times using the same mold before it deteriorates. This makes aluminum die casting highly suitable for the mass production of aluminum parts.

The Advantages of Aluminum Die Casting

Die casting aluminum provides numerous benefits compared to alternative metal-forming methods, which could deem it the ideal option for manufacturing your aluminum components. One key advantage is its capability to fabricate highly intricate shapes that cannot be efficiently achieved through extrusion or machining. A prime illustration of this is the manufacturing of intricate automotive components, such as transmissions and engine blocks. Other techniques struggle to maintain the level of complexity and precision needed for these specific products.

Moreover, die casting aluminum offers the flexibility of producing parts with either textured or smooth surfaces, as well as the capacity to cater to both large and small components.

The Top Considerations During Part Design

Several factors need to be considered when designing the part for casting. Initially, the mold should be created to allow the solidified aluminum part to be removed. The parting line, which indicates where the mold separates, must be taken into account during the early stages of die design. Additionally, the location of injection points is crucial. Multiple injection points can be incorporated into the die to prevent the molten metal from solidifying prematurely. This is particularly useful when there are cavities in the design, as surrounding them with aluminum ensures the part can still be removed when the mold is opened. Furthermore, the thickness of the part’s walls should be carefully considered. While there are no strict guidelines for minimum wall thickness due to advancements in technology, maintaining consistent wall thickness is generally preferred.

How it Compares to Green Sand and Permanent Mold Casting

Green sand and permanent mold are two popular alternatives to aluminum die casting. The green sand process involves using wet sand to form the mold for the casting, which makes it a more cost-effective option compared to the other two processes. In the image provided, you can observe an operator pouring molten metal into a sand cast mold.

On the other hand, permanent mold castings require the molten aluminum to be poured into the mold using gravity, unlike die casting which involves injection. Permanent mold castings have the potential to produce stronger casts.

However, die casting offers superior tolerances and better-finished surfaces when compared to the other two methods. In fact, it often eliminates the need for additional surface treatments.