Definition ofCNC Machining

CNC machining is a manufacturing technique that utilizes computer software to direct cutting tools and machinery. This innovation has transformed the manufacturing sector by allowing the creation of intricate parts with exceptional accuracy, speed, and effectiveness. This piece will delve into the fundamentals of CNC machining, its benefits, and its widespread use across different industries.

What is CNC Machining?

CNC machining involves the removal of material from a workpiece using cutting tools like mills, lathes, and drills. It starts with a CAD model that is translated into numerical codes or G-code. These codes are inputted into the CNC machine, which then directs the cutting tools to shape the part accordingly.

Types of CNC Machines

There are several types of CNC machines, each designed for specific applications:

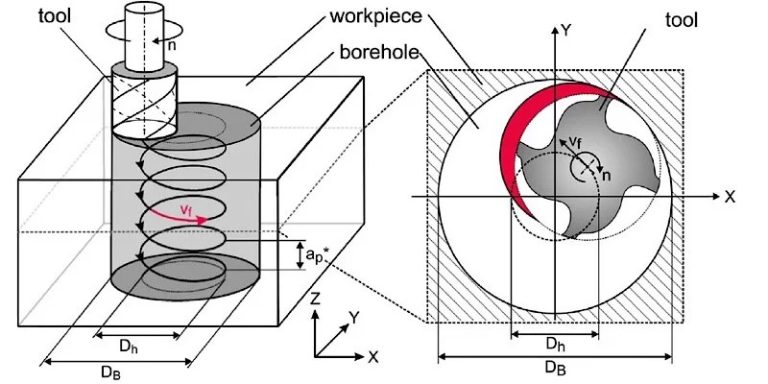

CNC Milling Machines:CNC Milling Machines utilize rotary cutting tools to eliminate material from a workpiece, enabling a range of operations including drilling, tapping, and contouring.

CNC Lathes:These machines, commonly referred to as turning centers, rotate the workpiece around a spindle while cutting tools are employed to remove material. They find widespread application in the production of cylindrical parts.

CNC Routers:These machines resemble milling machines, however, they generally feature a larger working space and are specifically designed for cutting softer materials such as wood, plastic, and foam.

CNC Plasma Cutters:The machines utilize a rapid stream of ionized gas to slice through electrically conductive materials such as steel, aluminum, and copper.

CNC Laser Cutters:Utilizing a concentrated laser beam, these devices are capable of cutting or engraving various materials, including metal, plastic, and wood.

Advantages of CNC Machining

CNC machining offers several benefits over traditional manufacturing methods:

Precision:CNC machines are capable of achieving very precise tolerances and manufacturing components with detailed designs and intricate shapes.

Speed:CNC machines have the capability to function at high velocities and accomplish tasks swiftly, thereby minimizing the production time needed.

Efficiency: CNC machines necessitate minimal manual involvement, resulting in lower labor expenses and heightened efficiency.

Consistency: CNC machines have the capability to manufacture parts that are identical in nature and possess consistent quality, regardless of the scale of production.

Flexibility: CNC machines possess the capability to swiftly and effortlessly undergo reprogramming in order to adapt to alterations in design or fabricate novel components.

Applications of CNC Machining

CNC machining is widely used across a range of industries, including:

Aerospace: CNC machining plays a vital role in the manufacturing of precise parts for airplanes, spacecraft, and satellites.

Automotive: CNC machines are employed in the production of engine components, suspension parts, and body panels for automobiles and trucks.

Medical: CNC machining is utilized in the production of surgical instruments, orthopedic implants, and diagnostic equipment.

Electronics:CNC machines are utilized in the manufacturing of circuit boards, enclosures, and various electronic components.

Energy:CNC machining plays a crucial role in manufacturing parts for wind turbines, solar panels, and various energy systems.

Choose MXY for Your CNC Machining Needs

CNC machining plays a crucial role in modern manufacturing, delivering unmatched precision, speed, and efficiency. With a solid grasp of CNC machining fundamentals and its diverse applications, manufacturers can harness this technology to create top-notch components for various industries. As CNC technology progresses, we anticipate even more groundbreaking innovations and capabilities in the days ahead. MXY stands as a reputable CNC machining facility with over a decade of expertise in manufacturing and rapid prototyping. Our adept team offers robust assistance for your upcoming projects, ensuring 100% compliance with your specifications. Through standardized management practices, we enforce stringent quality control measures for parts and products, while our streamlined work processes result in cost savings without compromising quality. Feel free to reach out to us for consultation!