Table of Contents

a new generation of mold CAD/CAM software technology

Currently, the mold software created by the United Kingdom, the United States, Germany, and other nations, along with certain Chinese universities and research institutes, possesses intelligent features, integration capabilities, mold manufacturability evaluation, and more. This software represents a cutting-edge generation of mold CAD/CAM software.anodized cnc machining services brass die casting

The next iteration of mold software ought to rely on a comprehensive compilation of mold design practices. This knowledge should be systematically and scientifically organized, with the engineering knowledge base stored in a specific format that facilitates mold retrieval. With the aid of intelligent software, mold CAD will no longer mimic traditional design calculation methods. Instead, it will leverage advanced design theories and draw upon expert knowledge and successful field experiences. As a result, the design outcomes will undoubtedly be both rational and cutting-edge.machining services custom cnc machining

The most recent mold software integrates the concept of three-dimensional design thinking, enabling the creation of mold structures in an intuitive manner.on. The 3D structure data produced can be seamlessly utilized for assessing mold manufacturing in NC machining, involving 3D parametric feature modeling, molding process simulation, NC machining process simulation, data exchange, and organizational management to a significant extent. It boasts high integration and perfection. Evaluating software integration involves not only checking the completeness of functional modules but also ensuring that these modules utilize the same data model, forming a unified global dynamic database for integrated management and information sharing. This software supports the entire mold design, manufacturing, assembly, testing, and debugging process.cnc machining for aluminum

The assessment of manufacturability in mold design software is crucial for ensuring optimal results. This function not only filters through various design options, but also assesses the efficiency and cost-effectiveness of the mold design process. Ultimately, it serves as a valuable tool for mold designers to make necessary adjustments.cnc precision machining parts

Manufacturability assessment encompasses the assessment of mold design and estimation of manufacturing costs, evaluation of mold assembly, evaluation of the manufacturing process for mold parts, and evaluation of mold structure and formability. The next generation of software should also incorporate assembly-oriented functions, as the functionality of the mold can only be fully realized through its assembly structure. By adopting an assembly-oriented design approach, mold assembly is no longer a mere assembly of individual parts. The data structure not only describes the functionality of the mold but also defines the relationships between the parts, thereby effectively achieving mold quality.milling parts custom metal cnc machining services

mold manufacturing technology

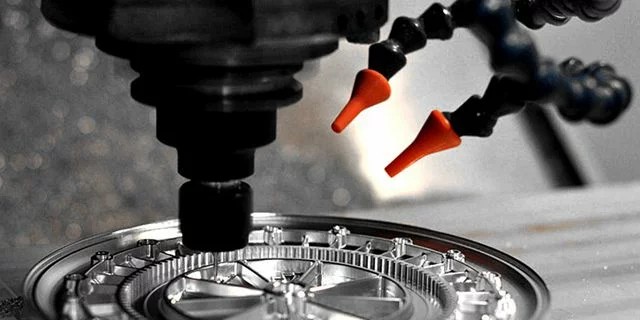

The swift advancement of mold manufacturing technology has emerged as a crucial component of contemporary manufacturing technology. One example of vertical CNC machining includes various mold-related technologies such as mold CAD/CAM, mold laser rapid prototyping, mold precision molding, mold ultra-precision processing, mold design using finite element method, and boundary element method for flow, cooling, heat transfer process dynamic simulation technology, mold CIMS technology, the progress of mold DNM technology and numerical control technology, essentially encompasses all aspects of modern manufacturing technology.machining center cnc milling.Presently, mold manufacturing technology is progressing towards expediting information drive, enhancing manufacturing flexibility, agile manufacturing, and systematic integration.cnc machining parts stainless steel

the third generation of mold technology | high-speed milling

High-speed milling

High-speed milling possesses several key characteristics, including high speed, precise processing, and exceptional surface quality.machining cnc cleaner pvc Additionally, it offers the advantage of low temperature, with the workpiece experiencing only a minimal increase of 3°C. cheap cnc machining service This is in stark contrast to traditional cutting methods, which often result in significant thermal deformation. cnc parts machining As a result, high-speed milling is particularly well-suited for materials that are sensitive to temperature-induced deformation, such as magnesium alloys.

Furthermore, due to its low cutting force, it is ideal for processing thin-walled and rigid parts.machining centre cnc By carefully selecting the appropriate tools and cutting parameters, high-speed milling can also achieve the benefits of processing hard materials (HRC60). cnc machining 3040 Consequently, high-speed milling technology remains a highly relevant and widely discussed topic, with ongoing advancements focused on enhancing agility, intelligence, and integration. brass cnc machining In fact, it is considered the third generation modeling technology.cnc machining parts manufacturers

Edm milling and “green” product technology

EDM

From an international perspective, electrical discharge machining (EDM) technology has achieved a high level of performance, process indicators, intelligence, automation, and other aspects. Currently, the latest trend in foreign countries is the exploration and advancement of EDM milling technology (EDM machining technology), which involves utilizing the high-speed rotation of basic tubular electrodes for three-dimensional or two-dimensional processing as a substitute for the conventional cavity electrode processing technique. This signifies a significant advancement in the realm of EDM as it eliminates the necessity for intricate molded electrodes.coating surface treatment oem metal cnc machining

With the continuous progress of EDM technology, the focus on safety protection technology for EDM has significantly increased. Many motors are now regarded as safety protection technology. Currently, the European Union has mandated that machines lacking the “CE” mark are not permitted to enter the EU market. Moreover, the global market is increasingly emphasizing the need for safety protection technical requirements.large cnc machining.In the global market, there is a growing emphasis on “green” products. Consequently, the EDM machine tool, being a prominent equipment for mold processing, must address this concern in the coming years.machined custom cnc machining

Advanced manufacturing technology

fast mold

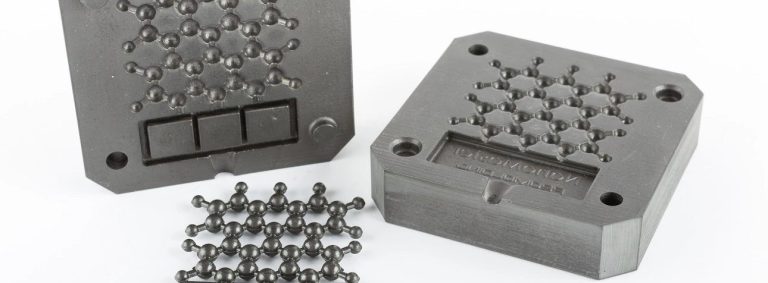

China has successfully achieved international standards and made significant progress in the field of laser rapid prototyping (RPM), leading to its gradual commercialization. The prominent commercialized rapid prototyping techniques globally include stereolithography (SLA), layered separation manufacturing (LOM), selective laser sintering (SLS), and 3D printing (3D-P).songshen cnc machining.Tsinghua University initially implemented SLA250 technology and equipment from a US-based 3D company, focusing on research and development. Following extensive efforts and enhancements, they successfully introduced the “M-RPMS- multi-function rapid prototyping manufacturing system” (comprising LOM-SSM, melt extrusion -MEM). This system stands out globally as the sole one with China’s proprietary intellectual property rights, including two rapid prototyping process rights (national patent), offering superior cost-effectiveness.5 axis machining cnc

The die-less multi-point forming technology is an innovative manufacturing technique that employs an adjustable punch group to substitute the conventional die. By utilizing CAD/CAM/CAT technology as the primary method, the multi-point forming system enables rapid and cost-effective automatic formation of 3D surfaces. Jilin University of Technology is responsible for the national key scientific and technological research project on moldless forming, and has autonomously developed and produced cutting-edge moldless multi-point forming equipment.cnc turning milling machining service

China’s technology is currently at the forefront in the practical application of theoretical research, surpassing institutions such as the Massachusetts Institute of Technology (MIT), the University of Tokyo in Japan, and the Tokyo Institute of Technology. China is actively advancing the field through promotion and application efforts.cnc machining products

The utilization of resin stamping die in the trial production of domestic cars has been successful for the first time. Faw Mold Manufacturing Co., Ltd. has designed and produced 12 sets of resin molds specifically for the trial production of new cars. These 12 sets of molds are utilized for creating large and intricate internal and external covers such as luggage, hood, front and rear fenders. The key characteristics of these molds include the processing of the mold surface based on CAD/CAM main model, the use of high strength resin casting molding from Swiss Ciba, and the control of mold gap through imported special wax sheet. These molds exhibit high precision in terms of size, allowing for a shortened manufacturing cycle of 1/2 to 2/3 and a cost saving of 10 million yuan (for the 12 sets of molds). This breakthrough has paved the way for a new approach to small car trial production, marking a significant milestone in China. According to Swiss Ciba experts, this achievement aligns with the international standards of the 1990s.machining services plastic cnc milling

On-site mold testing technology

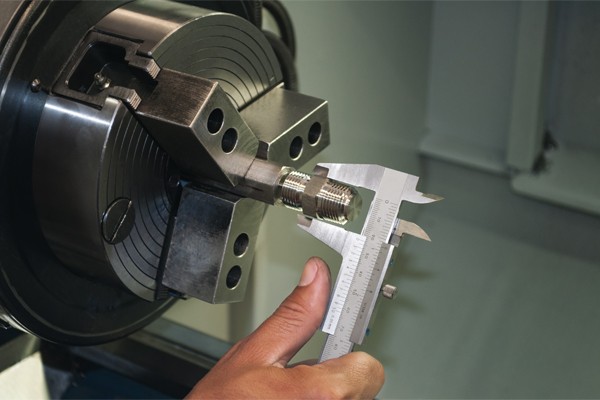

accurate measurement

The location of precision mold development has led to an increasing demand for accurate measurement. For a considerable period, the use of precision CMM has been restricted due to environmental limitations, resulting in its infrequent utilization in production sites. However, the latest generation of CMM possesses temperature compensation and anti-vibration materials, along with dust prevention measures, enhancing its adaptability and reliability in various environments. Consequently, it can be effortlessly installed in workshops to accomplish precise workpiece measurements.cnc machining aluminum

mirror polishing mold surface engineering technology

Die polishing technology

Die polishing technology plays a crucial role in both die surface engineering and the overall die manufacturing process.engine cnc machining

Currently, domestic polishing tools are capable of achieving a polishing level of Ra0.05μm. The abrasive abrasives and processes employed are generally sufficient to meet the requirements. However, when it comes to achieving a mirror-like polishing level of Ra0.025μm, the equipment, abrasive abrasives, and processes are still in the experimental phase.horizontal machining center cnc

Currently, domestic polishing equipment, grinding tools, and technologies have the capability to achieve an ultra-fine surface roughness of Ra0.05μm, which effectively fulfills the requirements. However, it is important to note that the exploration of the ultra-fine surface roughness of Ra0.05μm is still ongoing.5 axis cnc machining center automatic

The widespread use of mirror injection molds in manufacturing has made die polishing technology a critical concern. Due to existing challenges with polishing techniques and materials in China, including defects in lenses, injection molds, CDS, VCDS, and tools with superior transparency, a significant portion of injection molds continue to be imported.cnc service machining parts

It should be emphasized that the quality of the die surface polishing is influenced not only by the polishing equipment and techniques, but also by the mirror finish of the die material, a factor that has not received sufficient attention. Essentially, the polishing process is constrained by the mold material itself. For instance, when using 45# carbon steel as the mold material and polishing it to Ra0.2m, any visible defects can only be improved by enhancing the brightness through further polishing, as the roughness cannot be effectively enhanced. Consequently, in the current scenario, domestically produced mirror molds predominantly utilize imported mold materials like Sweden ASSAB 136, Japan Datong PD555, to achieve the desired mirror finish.cnc machining center x2000