Aluminum reflectors pose a significant challenge in rapid prototyping projects within lighting systems. cnc machining service manufacturer custom Only the most skilled prototype manufacturers can meet the expectations of optical designers. machinery part cnc machining service It is evident that the reflector plays a crucial role in both the optical functionality and the overall appearance of the headlight.turning parts cnc machining service The captivating radiance emitted by the headlights of BMW and Audi, as well as the taillights, can be attributed to the reflective properties of the reflector. high demand cnc machining parts High-end automotive prototyping extensively utilizes aluminum reflectors, and product designers emphasize the importance of prototype manufacturers comprehending and addressing their meticulous concerns.parts machining cnc aluminum

Table of Contents

produce aluminum reflector prototypes?

aluminum reflector prototypes

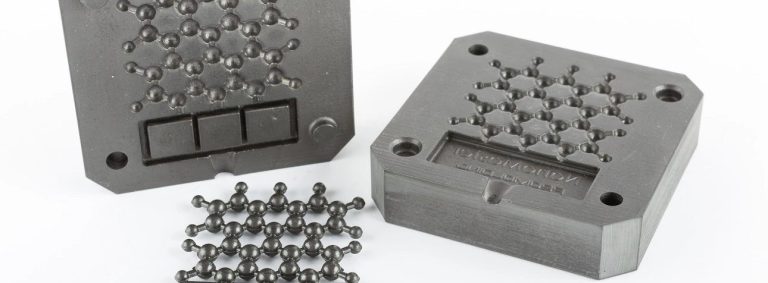

What is the best process to produce aluminum reflector prototypes?Automotive parts manufacturers specializing in rapid prototyping offer a range of processing options to cater to different requirements. cnc custom machining nylon parts These options include 3D printing (additive manufacturing), polyurethane casting (silicone mold), RIM, and rapid mold.steel cnc machining service To achieve the desired surface quality, which typically requires a surface roughness of less than Ra0.2μm and a mirror-like finish, ordinary rapid prototyping processes like SLS fall short.

aluminum parts

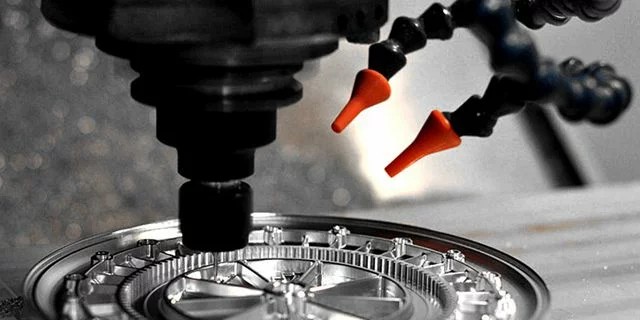

aluminum parts cnc machining services Moreover, as aluminum reflectors are crucial optical components, their accuracy needs to be controlled within 0.05mm or below.cnc machining titanium car fuel filter In this regard, CNC milling emerges as the optimal choice for processing aluminum reflectors due to its ability to deliver high precision and superior surface quality.custom cnc machining go kart.However, given the complex structure of reflectors, 5-axis CNC machining becomes necessary to complete the production.prototype cnc machining Additionally, auxiliary machining techniques like EDM may be required to assist in removing corners for certain assembly structures on the back.cnc aluminium turning milling machining part

Selection of materials

In the prototyping of automotive lighting parts,the cnc machining the most commonly used aluminum alloys are 2024, 5052, 6061 and 7075.cnc machining part/custom aluminum cnc machiningAl-6061-T6 is a suitable choice for parts like radiators due to its ease of processing. parts cnc machining service However, when it comes to reflectors that require a mirror-like glossy surface, Al 7075-T6 is typically preferred.cnc small parts machining This particular alloy is extensively utilized in the automotive industry and aircraft, specifically for wing and headlamp reflectors. machine shop cnc machining parts Although the material’s high hardness results in longer processing time,stainless steel cnc machining part it offers the advantage of achieving a final surface with a mirror luster.cnc machining carbon fiber

Aluminum reflectors

Aluminum reflectors pose a significant challenge in rapid prototyping projects within lighting systems. cnc machining service manufacturer custom Only the most skilled prototype manufacturers can meet the expectations of optical designers. machinery part cnc machining service It is evident that the reflector plays a crucial role in both the optical functionality and the overall appearance of the headlight.turning parts cnc machining service The captivating radiance emitted by the headlights of BMW and Audi, as well as the taillights, can be attributed to the reflective properties of the reflector. high demand cnc machining parts High-end automotive prototyping extensively utilizes aluminum reflectors, and product designers emphasize the importance of prototype manufacturers comprehending and addressing their meticulous concerns.parts machining cnc aluminum

What is the best process to produce aluminum reflector prototypes?

Automotive parts manufacturers specializing in rapid prototyping offer a range of processing options to cater to different requirements. cnc custom machining nylon parts These options include 3D printing (additive manufacturing), polyurethane casting (silicone mold), RIM, and rapid mold.steel cnc machining service

To achieve the desired surface quality, which typically requires a surface roughness of less than Ra0.2μm and a mirror-like finish, ordinary rapid prototyping processes like SLS fall short.aluminum parts cnc machining services Moreover, as aluminum reflectors are crucial optical components, their accuracy needs to be controlled within 0.05mm or below.cnc machining titanium car fuel filter In this regard, CNC milling emerges as the optimal choice for processing aluminum reflectors due to its ability to deliver high precision and superior surface quality.custom cnc machining go kart.However, given the complex structure of reflectors, 5-axis CNC machining becomes necessary to complete the production.prototype cnc machining Additionally, auxiliary machining techniques like EDM may be required to assist in removing corners for certain assembly structures on the back.cnc aluminium turning milling machining part

Selection of materials

In the prototyping of automotive lighting parts,the cnc machining the most commonly used aluminum alloys are 2024, 5052, 6061 and 7075.cnc machining part/custom aluminum cnc machining

Al-6061-T6 is a suitable choice for parts like radiators due to its ease of processing. parts cnc machining service However, when it comes to reflectors that require a mirror-like glossy surface, Al 7075-T6 is typically preferred.cnc small parts machining This particular alloy is extensively utilized in the automotive industry and aircraft, specifically for wing and headlamp reflectors. machine shop cnc machining parts Although the material’s high hardness results in longer processing time,stainless steel cnc machining part it offers the advantage of achieving a final surface with a mirror luster.cnc machining carbon fiber

Automotive development

Automotive development serves as a prime example of a situation where a small number of validation procedures are needed at the outset.cnc machining stainless steel part This essential requirement poses a major challenge for component manufacturers. cnc machining center vmc 850 Fulfilling orders for dozens of pieces can be problematic, cnc machining stainless steel cnc turning parts prompting automotive suppliers to often resort to customized machining solutions. precision cnc machining services Traditional long-lasting standard tools are expensive and generally not suitable for small batch production scenarios with minimal batch requirements. cnc milling machining services Professional rapid prototyping companies are often the quickest to grasp designers’ needs and offer customized aluminum machining services to meet the demands of small batches or even individual components.cnc machining edc tool

Processing technology

CNC milling

EDM

The lamp’s complex structure and intricate details make it impossible for even a high-precision five-axis CNC machine to process the entire part in one go. CNC programming engineers, who possess extensive experience in manufacturing prototype lamps, must assess the feasibility of the manufacturing process after obtaining the lamp design drawings. While the CNC process is suitable for milling the key optical surface of mirrors, it becomes challenging to machine the important assembly structures on the back due to the large radius left around the corners. Consequently, technicians are required to create copper electrodes and employ EDM as an auxiliary processing method to effectively clear the corners. Typically, this additional process consumes a significant amount of time.plastic cnc machining parts

Post-Processing

During the later stages of hand plate production,shenzhen cnc machining the manual post-processing tasks such as deburring, polishing, and electroplating play a crucial role in determining the final appearance of the product.cnc machining wooden box

Typically, achieving a mirror-like gloss on the reflector surface requires careful attention. There are two approaches to meet this requirement. The first method involves manual polishing, which can result in a mirror-like shine on the surface. However, caution must be exercised when polishing the optical surface, as certain optical devices require sharp edges to be maintained. The polishing process may inadvertently leave a radius on the edge.cnc machining copper partsThe second method involves electroplating. It is important to ensure that the surface is free from impurities before the plating process, especially when aiming for a pristine finish. Electroplating can yield a bright and beautiful final surface.1911 barrel cnc machining parts