Aluminum offers a unique advantage as a versatile element that finds practical applications across various industries.cnc machining plastic cabinets Its exceptional properties position it as a top choice material for a wide range of uses.suspention parts cnc machining Noteworthy characteristics such as its lightweight nature and flexibility make it particularly well-suited for applications in sectors like automotive manufacturing, aerospace technology, and power generation.cnc machining prototype.It has the capability to manufacture significant components of automobiles,cnc machining turning service including reflectors found in headlights.cnc machining for cutting This phase employs CNC machining technology, enabling the creation of aluminum CNC reflectors through various programs. 5axis cnc machining controller Among the techniques utilized for producing these reflectors is milling,cnc machining for chipboard a production process that has been in existence since the 19th century.precision cnc turning machining Even today, numerous car manufacturers continue to utilize this method.custom machining cnc

Numerical control milling

This process entails the utilization of cutting equipment to crush a layer of material from an object formed using any other machine or tool.machining centre parts cnc This is entirely distinct from the addition of multiple layers in 3D printing.watch case cnc machining The procedure originated from the common practice of rotating files in the 19th century.xiamen cnc machining part The milling process has undergone significant advancements and witnessed numerous technological improvements,cnc machining center 1300 serving as the foundation for the CNC milling employed today.price machining cnc.CNC machining is an alternative form of milling.cnc machining parts set Often referred to as computer numerical control,cnc machining center 4 axis it involves the automation of tool equipment through the use of computers that execute a series of programmed machine management instructions to facilitate various tasks.shafts for precise cnc machining The different models are created using computer-aided design (CAD) software.advance cnc machining

All CAD-created parts encompass dimensions,top quality cnc machining parts appearance, dimensional space, and other materials. Subsequently, they are transferred to production orders via computer-aided manufacturing software. This software provides detailed instructions for the model, which are then inputted into the CNC machine to initiate the production process. Another notable feature is that the computer-operated milling machine is vertical and capable of moving along the Z-axis. This allows for enhanced speed and precision. There is a wide range of affordable CNC milling machines available.cnc machining workshop

Inhoudsopgave

Milling process

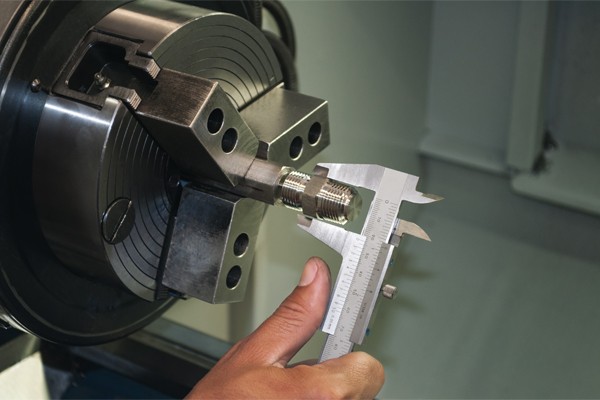

The milling operation must be conducted by skilled professionals who will oversee the milling machine’s operation.cnc machining center for aluminum The milling process consists of various stages that need to be completed in order to achieve the final product. Initially, a decision must be made on whether to proceed with batch production or small batch production of parts. Subsequently, it is essential to review the diagrams provided by the engineer or expert and adhere to the established blueprint.quanzhou cnc machining

Nowadays, individuals have the ability to propose or design using computer-aided design or manufacturing systems. The computer numerical control center centralizes the clamping device, tooling device, and the object being processed. Adjust parameters such as speed, shape, and cutting based on the initial plan or specific requirements. It is crucial to conduct maintenance and execute various processes at the appropriate times to maintain the necessary dimensions and functions throughout the process.cnc machining slide

CNC machining programs are commonly utilized in manufacturing facilities to accurately produce 3D components, particularly in the manufacturing of automotive reflective covers.cnc custom machining

The manufacturing of automotive components, such as reflectors, presents challenges for various companies. The intricate shape and high level of precision required make the production process extremely difficult for most manufacturers. Among the materials that can be utilized to create flawless automotive parts, aluminum stands out.fujian cnc machining

As previously mentioned, aluminum is not only durable and easy to work with, but it is also lightweight and resistant to degradation. Its exceptional heat conductivity and ability to reflect both heat and light make it the optimal choice for automotive mirrors. Additionally, aluminum can be employed in the fabrication of other components within the automotive industry. In fact, certain parts of aircraft and other flying objects can also be constructed using aluminum.cnc machining center awea

In addition to aluminum, there are other techniques that can be employed during the manufacturing process. Electrical discharge machining and various post-finishing practices are commonly utilized. Electrical discharge machining involves the use of electrical discharges to achieve the desired shape or finish of an automotive reflector. Polishing and electroplating are among the most frequently employed finishing practices, aimed at enhancing surface quality. These techniques not only improve the visual characteristics of the parts but also enhance their resistance to wear, all of which are achieved through CNC machining.cnc machining service formal

Relevance of CNC machining in the automotive industry and aluminum parts manufacturing

CNC machining offers numerous advantages in the production of auto parts, one of which is its speed. By utilizing programmed or computerized operations, the entire process is expedited, making it highly suitable for mass production of top-notch parts. Moreover, this procedure eliminates any possibility of failures or errors, allowing for enhanced functionality and the development of highly accurate components.cnc machining services router

Another advantage of CNC machining is its reduced labor requirement. Since most operations are programmed, only one engineer may be needed to oversee various tasks, resulting in significant savings on labor costs. Additionally, this process ensures high precision production, as cutting tools precisely shape different materials, resulting in impeccable finishing and parts with exceptionally precise surfaces.mini cnc machining multifunctional

conclusion

The utilization of aluminum in the fabrication of automotive components has been simplified thanks to CNC milling techniques. The accuracy achieved in manufacturing these parts is a key factor in their utility. High-quality parts can be manufactured through this method with ease. Furthermore, the CNC milling process is efficient and straightforward in comparison to alternative manufacturing methods. It is recommended to explore the use of CNC milling for the production of top-notch automotive parts.mechanical parts cnc machining