Inhoudsopgave

How do you select the right CNC materials?

Proper material selection

Proper material selection is crucial when designing a component for CNC machining. Below are the fundamental guidelines we suggest adhering to in order to choose the appropriate materials for your bespoke parts.

- Specify the material specifications: These specifications encompass mechanical, thermal, and other material requirements, along with considerations of cost and surface finish. Take into account the intended application and the environmental conditions the parts will be subjected to.

- Determine potential materials: Narrow down a selection of materials that meet all or most of your design requirements.

- Choose the optimal material: Typically, a trade-off is necessary when selecting the most suitable material, balancing multiple design requirements such as mechanical performance and cost.

In this article, our main emphasis will be on the second step. By utilizing the information provid

What are Protolabs Network’s guidelines for choosing materials for CNC?

key characteristics

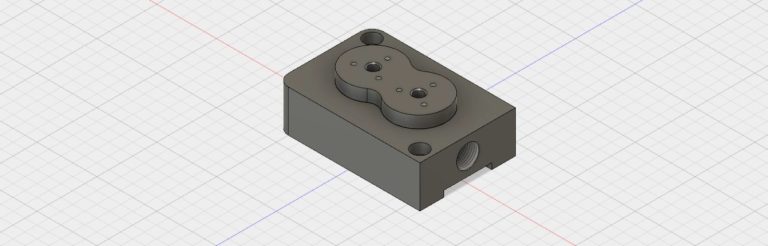

The tables provided below offer a summary of the key characteristics of the most commonly used CNC materials. The information provided has been gathered from the datasheets provided by the manufacturers of the materials.cnc spare part machining Metals and plastics have been classified separately based on their unique properties and uses.cnc machining 3040 Metals are typically utilized in scenarios where high strength, hardness, and thermal resistance are essential. On the other hand, plastics are lightweight materials with a diverse range of physical attributes, often chosen for their chemical resistance and electrical insulation properties.

Our analysis of CNC materials concentrates on factors such as mechanical strength (measured by tensile yield strength), machinability (which impacts CNC pricing), cost, hardness (primarily for metals), and temperature resistance (primarily for plastics).

For a quick reference to identify CNC materials that align with specific engineering requirements, refer to the infographic provided.

25 commonly used materials

This comprehensive guide offers a detailed analysis of the 25 commonly used materials in CNC machining, assisting you in choosing the most suitable one for your specific needs.brass cnc machining

CNC machining possesses the ability to produce components using an extensive range of metals and plastics.carbon graphite cnc machining Given the vast array of materials available for CNC milling and turning, selecting the most appropriate one for your specific requirements can present a considerable obstacle.cnc machining edc tool.It is essential to comprehend the benefits and ideal applications of each material option. This article delves into a comparison of the prevalent CNC materials, focusing on their mechanical and thermal characteristics, costs, as well as typical and recommend uses.

What is aluminum? The robust, economical alloy

Aluminum

- Aluminum alloys are recognized for their excellent strength-to-weight ratio, as well as their high thermal and electrical conductivity, and natural resistance to corrosion.cnc 3 axis vertical machining They are easily machined and cost-effective when mass-produced, which is why they are widely used for creating prototypes and different components.parts machining cnc aluminum

- Despite typically having lower strength and hardness than steels, aluminum alloys can undergo anodization to create a long-lasting protective coating on their surfaces.steel cnc machining service

classifications of aluminum

Now, let us explore the diverse classifications of aluminum alloys.used cnc machining doosan puma

Aluminum 6061 is extensively used as a versatile aluminum alloy due to its favorable strength-to-weight ratio and impressive machinability.cnc machining center 3 axis Conversely, Aluminum 6082 has a similar composition and material properties to 6061, but it is more commonly utilized in Europe as it adheres to British Standards.vertical machining center cnc 15000rpm In the field of aerospace applications where weight reduction is crucial, Aluminum 7075 takes the lead as the most frequently employed alloy.cnc machining service atm pinpad cover atm keypad 3d Not only does it possess exceptional fatigue properties, but it can also be heat treated to achieve high strength and hardness, making it comparable to steels.part cnc machining On the other hand, Aluminum 5083 surpasses most other aluminum alloys in terms of strength and exhibits exceptional resistance to seawater.bushing machining cnc This makes it an optimal choice for construction and marine applications.custom cnc machining go kart Additionally, it is highly recommended for welding purposes.

Material characteristics:

- Typical density of aluminum alloys: 2.65-2.80 g/cm3

- Can be anodized

- Non-magnetic

What is stainless steel? The strong, durable alloy

Stainless steel alloys

Stainless steel alloys exhibit exceptional characteristics including high strength, excellent ductility, remarkable resistance to corrosion and wear, as well as the capability to be easily welded, machined, and polished.cnc machining bezel The magnetic properties of these alloys depend on their specific composition.cnc aluminium turning milling machining part

Let’s analyze the different types of stainless steel available on our platform.cnc machining part/custom aluminum cnc machining

Stainless steel 304 is the most commonly utilized stainless steel alloy, recognized for its exceptional mechanical properties and ease of machinability.custom cnc machining racing It boasts high resistance to various environmental factors and corrosive agents.cnc machining carbon fiber

stainless steel 316

On the other hand, stainless steel 316 is another popular stainless steel alloy that shares similar mechanical properties with 304. However, it provides enhanced resistance to corrosion and chemicals, especially against saline solutions like seawater, making it perfect for challenging environments.plastic cnc machining parts

Stainless steel 2205 Duplex is known for its superior strength compared to other stainless steel alloys, with exceptional corrosion resistance.cnc machining metal parts This alloy is commonly used in extreme environments, particularly in the Oil & Gas industry.cnc machining wooden box

Stainless steel 303 is valued for its toughness, although it has slightly lower corrosion resistance than 304.cnc precision automatic lathe machining Its excellent machinability makes it a popular choice for high-volume applications, such as manufacturing aerospace nuts and bolts.cnc machining copper parts

Stainless steel 17-4 (SAE grade 630) has mechanical properties similar to 304 but can be precipitation hardened to a high degree, similar to tool steels.cnc machining heater copper parts With outstanding chemical resistance, this alloy is ideal for demanding applications like producing wind turbine blades.1911 barrel cnc machining parts

Material characteristics:

Standard density ranges from 7.7 to 8.0 grams per cubic centimeter.cnc vertical machining center trade Non-magnetic stainless steel types include 304, 316, and 303.component metal machining parts cnc aluminium Magnetic stainless steel varieties consist of 2205 Duplex and 17-4.cnc machining stainless steel part

What is mild steel? The general purpose alloy

Mild steels

Mild steels, also known as low-carbon steels, possess advantageous mechanical properties, exceptional machinability, and commendable weldability.cnc machining center 3 axis hidenhain They are extensively utilized by manufacturers for various general-purpose applications, such as jigs and fixtures, due to their affordable price.craphite machining cnc However, mild steels are susceptible to corrosion and chemical deterioration.cnc machining center vmc 850

different types of mild steels

Let us now examine the different types of mild steels available on the platform.cnc machining stainless steel cnc turning parts

Mild steel 1018 is a versatile alloy that is renowned for its ease of machining and welding, as well as its impressive combination of toughness, strength, and hardness.cnc machining components It is widely acknowledged as the most commonly used mild steel alloy.precision cnc machining services

Mild steel 1045 is categorized as a medium carbon steel that offers excellent weldability, machinability, and notable strength and impact resistance.cnc milling machining services

Mild steel A36 is a popular choice for structural purposes because of its good weldability, making it suitable for a wide range of industrial and construction applications.cnc machining service manufacturer custom

Material characteristics:

Typical density: 7.8-7.9 g/cm3

Magnetic

What is alloy steel?

alloy steels

Furthermore, alloy steels encompass a range of alloying elements in addition to carbon, which significantly augment their hardness, toughness, fatigue, and wear resistance.cnc machining works Similar to mild steels, alloy steels are susceptible to corrosion and chemical assaults.machinery part cnc machining service Alloy steel 4140 showcases remarkable mechanical characteristics as a whole, demonstrating exceptional durability and resilience.cnc precision machining turning parts cnc machining service It finds suitability in numerous industrial applications, although welding is not advised for this alloy.

Material characteristics:

- Typical density: 7.8-7.9 g/cm3

- Magnetic

What is tool steel?

Tool steels

Tool steels are a category of metal alloys that exhibit exceptional attributes, such as elevated hardness, rigidity, resistance to abrasion, and thermal endurance.copper cnc machining These remarkable properties are attained through the application of heat treatment techniques.curvic coupling cnc machining Tool steels find their primary application in the fabrication of manufacturing tools, specifically dies, stamps, and molds, which justifies their fitting designation.high demand cnc machining parts Let’s break down the tool steels we offer at Protolabs Network. Tool steel D2 is a wear-resistant alloy that retains its hardness up to 425°C.machine shop cnc machining It is often used in the fabrication of cutting tools and dies.cnc custom machining nylon parts Tool steel A2 is a general-purpose tool steel that is air-hardened, renowned for its excellent toughness and dimensional stability at elevated temperatures.cnc milling lathing machining It is widely used in the creation of injection molding dies.aluminum parts cnc machining services Tool steel O1 is an oil-hardened alloy with a hardness of 65 HRC.cnc metal machining part It is frequently employed in the manufacturing of knives and cutting tools.cnc machining titanium car fuel filter

Material characteristics:

Typical density: 7.8 g/cm3

Typical hardness: 45-65 HRC

What is brass? The conductive & cosmetic alloy

Brass

Brass is a metal alloy recognized for its excellent machinability and remarkable electrical conductivity, making it a popular choice for applications requiring low friction.cnc machining services shop Architectural elements, including ornamental brass components adorned with gold accents, often incorporate this material.prototype cnc machining

Here’s the brass we offer at Protolabs Network.

Brass C36000 possesses excellent tensile strength and inherent resistance to corrosion. Due to its exceptional machinability, it is frequently chosen for high-volume applications.

Material characteristics:

Typical density: 8.4-8.7 g/cm3

Non-magnetic

What is ABS? The prototyping thermoplastic

ABS

ABS is a commonly utilized thermoplastic substance recognized for its advantageous mechanical properties, remarkable ability to withstand impacts, high heat resistance, and ease of fabrication.ABS is characterized by its low density, making it an ideal choice for situations where minimizing weight is a priority.the cnc machining CNC-machined ABS components are frequently employed as prototypes before transitioning to mass production through injection molding.

Material characteristics:

Standard density range: 1.00-1.05 g/cm3.

What is nylon? The engineering thermoplastic

Polyamide (PA)

Polyamide (PA), also referred to as nylon, is a thermoplastic substance extensively employed in engineering applications due to its remarkable mechanical properties, robust impact resistance, and outstanding chemical and abrasion resistance. cnc machining fuel filter However, it has a tendency to absorb water and moisture.precision machined cnc machining Nylon 6 and nylon 66 are the grades that are most commonly used in CNC machining.parts cnc machining service

Material characteristics:

The standard density is 1.14 grams per cubic centimeter.cnc small parts machining

What is polycarbonate? The thermoplastic with impact strength

Polycarbonate

Polycarbonate is a thermoplastic variety renowned for its remarkable durability, effortless machinability, and outstanding ability to withstand impacts (exceeding that of ABS).brass cnc machining parts Although it is commonly transparent, it can also be dyed in a multitude of hues.machine shop cnc machining parts These qualities render it suitable for a diverse array of uses, such as in fluidic devices or automotive glazing.

Material characteristics:

Standard density range: 1.20-1.22 g/cm3.stainless steel cnc machining part

What is POM (Delrin)? The most machinable CNC plastic

POM

POM, also known as Delrin in the commercial market, is frequently selected for CNC machining plastic components that demand superior precision, stiffness, minimal friction, exceptional dimensional stability under high temperatures, and extremely low water absorption.

Material characteristics:

The standard density ranges from 1.40 to 1.42 g/cm3.shenzhen cnc machining

What is PTFE (Teflon)? The extreme temperature thermoplastic

PTFE

PTFE, commonly known as Teflon, is a type of engineering thermoplastic that is highly regarded for its outstanding chemical and thermal resistance, along with its extremely low coefficient of friction compared to other solid materials.cnc machining parts medical It is distinguished as one of the few plastics that can withstand temperatures above 200 degrees Celsius, making it an excellent electrical insulator.cnc turning aluminum machining Additionally, it boasts exceptional mechanical properties, often making it a suitable choice for use as a lining or insert in a variety of assemblies.cnc aluminium machining

Material characteristics:

Typical density: 2.2 g/cm3

What is HDPE? The outdoor & piping thermoplastic

HDPE

High-density polyethylene (HDPE) is a thermoplastic renowned for its remarkable strength-to-weight ratio, impressive resistance to impact, and dependable durability against diverse weather conditions.cnc machining parts for motorcycle Its lightweight characteristic renders it perfect for outdoor applications and piping systems.cnc machining gun parts Similar to ABS, HDPE is frequently employed in the production of prototypes prior to Injection Molding.

Material characteristics:

Typical density: 0.93-0.97 g/cm3

What is PEEK? The plastic to replace metal

PEEK

PEEK, a superior engineering thermoplastic, showcases impressive mechanical characteristics, exceptional thermal resistance over a broad temperature spectrum, and outstanding durability against a diverse range of chemicals.flashlight body aluminum cnc machining Because of its remarkable strength-to-weight ratio, PEEK is often used as a replacement for metal parts. Additionally, the presence of medical grades increases its appropriateness for biomedical uses.cnc machining parts formal

Material characteristics:

Typical density: 1.32 g/cm3