CNC machining of motorcycle accessories: precision and performance In the realm of motorcycles, all riders understand the inseparable connection between performance and style. Whether it’s a need for greater speed or a desire for a more appealing look, there is an increasing desire for top-notch motorcycle accessories. CNC machining plays a vital role in this domain by producing meticulously crafted parts that elevate both functionality and appearance.

The pinnacle of precision engineering

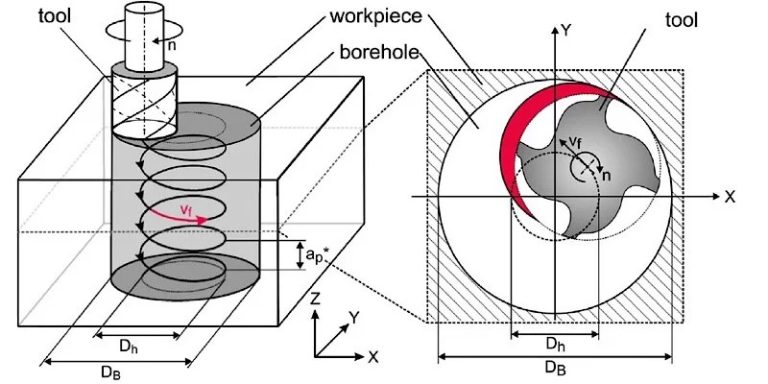

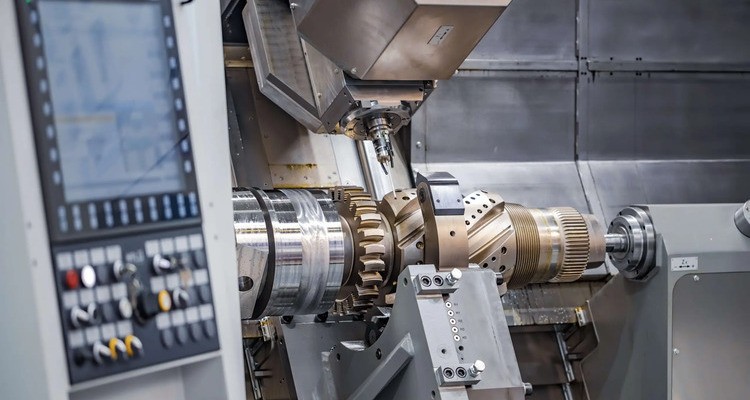

CNC machining is famous for its precision and consistency. It involves the use of computer-operated machines to accurately shape parts from materials like aluminum, steel, or titanium. Motorcycle lovers can rely on CNC machining to guarantee that each piece, from brake levers to foot pedals, mirrors, and handlebars, adheres to exact standards.

Strength and durability

One of the main advantages of CNC machining motorcycle accessories is the ability to produce parts that are not only accurate but also very strong. The components are rigorously tested to withstand the rigors of long drives, changeable weather conditions and violent vibrations. Whether it’s a custom brake tank cap or a set of rear parts, CNC machining guarantees durability without compromising weight or performance.

Customization options Every rider has their own distinctive style and preference when it comes to motorcycles. CNC machining offers unparalleled customization options, allowing manufacturers to produce custom parts that perfectly match individual specifications. Whether it’s engraving logos, incorporating complex designs, or creating components that seamlessly fit a particular motorcycle model, this level of customization not only enhances the motorcycle’s beauty

Promote technological innovation

As technology advances, CNC machining keeps evolving too. Manufacturers strive to enhance their techniques by utilizing state-of-the-art software and tools, enabling them to explore new horizons in motorcycle accessory design. This continuous innovation guarantees that riders can enjoy the latest lightweight materials, sleek aerodynamic shapes, and comfortable ergonomic designs.

Environment

CNC machining not only improves performance and aesthetics but also contributes to the sustainable evolution of the motorcycle industry. Through precision manufacturing that optimizes material usage and reduces waste, CNC machining lessens its environmental impact compared to traditional machining methods. This eco-friendly approach is favored by riders who value sustainability without compromising on quality.

Concentration

Motorcycle accessories owe much of their performance and style to CNC machining, which offers precision engineering, durability, and customization options. This makes it a top choice for riders and manufacturers looking to enhance their products. With technology progressing steadily, CNC machining is expected to remain a key player in shaping the future of motorcycles.

Whether you want to upgrade your bike’s performance or add a personalized element, CNC machining ensures that every accessory meets the highest standards of quality and reliability. Embrace the precision of CNC machining and experience the difference it can make for you In CNC machining motorcycle accessories, factories can play a number of key roles, as described below:

1.Manufacture high-precision parts The factory uses CNC machining technology to produce high-precision motorcycle parts. These accessories include brake handles, foot pedals, rearview mirror brackets, and so on, each part can be accurate to a few tens of millimeters of accuracy. This precision ensures the quality and reliability of the parts and improves the performance and safety of the vehicle.

2.Provide a diverse selection of materials The factory has the option to select from a range of materials based on the need, like aluminum alloy, stainless steel, titanium, etc., to create various types and designs of motorcycle accessories. Each material comes with its own distinct features – for instance, aluminum alloy is lightweight and sturdy, ideal for enhancing vehicle performance; Titanium boasts excellent corrosion resistance, making it perfect for components that require high durability.

3.Achieve mass production and customization requirements CNC machining technology enables factories to meet production requirements ranging from mass production to personalized customization. Whether producing parts in large quantities with identical specifications or creating custom parts in unique styles and sizes based on customer preferences, CNC machining ensures efficient completion of tasks while maintaining quality and consistency for each part.

4.Support fast design and iteration Due to the increasing market demand and advancements in technology, motorcycle accessories are constantly in need of quick adjustments and iterations in their design. Thanks to CNC machining, factories are able to swiftly respond to these design changes, resulting in reduced production cycles. This allows manufacturers and designers to stay ahead of the competition in a highly competitive market.

5.Improve product quality and durability CNC machining guarantees a high level of control over the manufacturing process for every component, minimizing human involvement and enhancing the quality and durability of the products. By employing precise machining techniques, the factory ensures that each part’s dimensions and surface quality adhere to the highest standards, surpassing customer expectations.

6.Promote innovation and market competitiveness The factory doesn’t just make motorcycle accessories through CNC machining; it also plays a crucial role in driving innovation and market competitiveness. Through constant improvement of technology and processes, as well as experimenting with new materials and designs, the factory offers customers a wider range of competitive product options, helping manufacturers differentiate themselves in the tough market.

In conclusion, the factory is essential for CNC machining motorcycle accessories, offering strong backing and assurance for the advancement and enhancement of the worldwide motorcycle industry with precise machining, various material options, adaptable production capabilities, and ongoing innovation drive.