In the modern manufacturing industry, CNC machining is considered a crucial technology.cnc machining set, CNC machine tools are highly regarded for their precision and efficiency, playing a significant role in industries such as aerospace, medical devices, automotive manufacturing, and electronic equipment.

CNC machining involves using a computer control system to automatically operate machine tools for processing tasks based on pre-programmed instructions. It offers significant advantages over traditional manual methods, such as increased precision, repeatability, efficiency, and flexibility.cnc machining set

Key advantages of CNC machining:

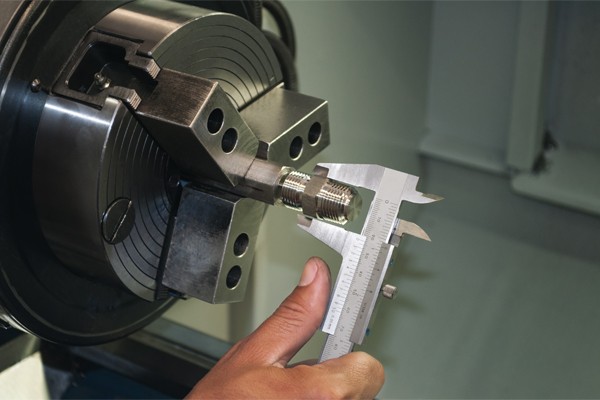

CNC machines can achieve micrometer precision, guaranteeing consistent part size and shape, surpassing the accuracy of manual machining.cnc machining set

CNC machines offer exceptional efficiency and productivity due to their automated processes. By minimizing human involvement and downtime, these machines can operate continuously, resulting in a significant boost to production efficiency.

CNC machines offer a remarkable level of flexibility and complexity.cnc machining set, By simply adjusting the program and tool path, these machines can effortlessly process a wide range of intricate part shapes, catering to diverse customer requirements.cnc machining set, This exceptional production flexibility ensures that customer needs are met with utmost precision.

In terms of cost-effectiveness,cnc machining set, CNC equipment may require a significant initial investment.cnc machining set, However, due to its remarkable efficiency and minimal waste,cnc machining set, it can ultimately lead to reduced production costs over time.

Applications of CNC machining in different industries:

Aerospace technology plays a crucial role in the production of aircraft parts and aeroengine components.cnc machining set, These industries demand utmost precision and lightweight materials to ensure optimal performance.

Medical devices: The production of complex surgical tools and prostheses requires safe materials, smooth surfaces and high accuracy. Automotive manufacturing: Processing engine parts, braking systems and interior components to ensure safety and performance. Electronic equipment: The production of circuit boards and precision components to ensure the stability and reliability of equipment. Future development trend:

Aerospace technology is employed to create aircraft parts and aeroengine components, demanding top-notch accuracy and lightweight construction.Overall, CNC machining is a key technology in modern manufacturing that boosts production efficiency and supports product quality and innovation across various industries. As technology advances and its applications grow, CNC machining will remain crucial in the global manufacturing sector.

By utilizing a CNC machining set in a plant, a range of essential services can be offered to meet various production needs and customer demands.The following are the main services that a factory can perform in a CNC machining set:

Customized processing services:CNC machining can precisely manufacture parts with intricate shapes and sizes based on the unique needs and design specifications of customers. This tailored service is crucial for sectors like aerospace, medical equipment, and luxury consumer goods.

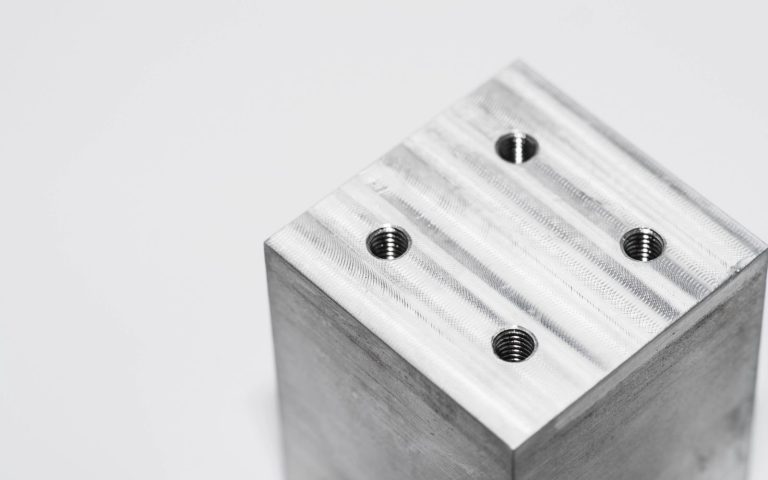

High precision machining:

CNC machines are capable of reaching micron-level precision, guaranteeing that parts adhere to design specifications in terms of size and shape. This is crucial for industries like automotive manufacturing, electronics, and precision instruments.

Mass production:

CNC machining offers high efficiency and repeatability, making it ideal for mass production requirements. Manufacturers can utilize CNC equipment to efficiently produce large quantities of identical or similar parts,cnc machining set, ultimately improving production efficiency and cost-effectiveness.

Quick response to market demand:

CNC machines are known for their flexibility and quick adjustment capabilities,cnc machining set, enabling factories to swiftly respond to shifts in market demand. With the ability to modify processing procedures and operations,cnc machining set, it becomes feasible to manufacture new products or meet new design specifications promptly.

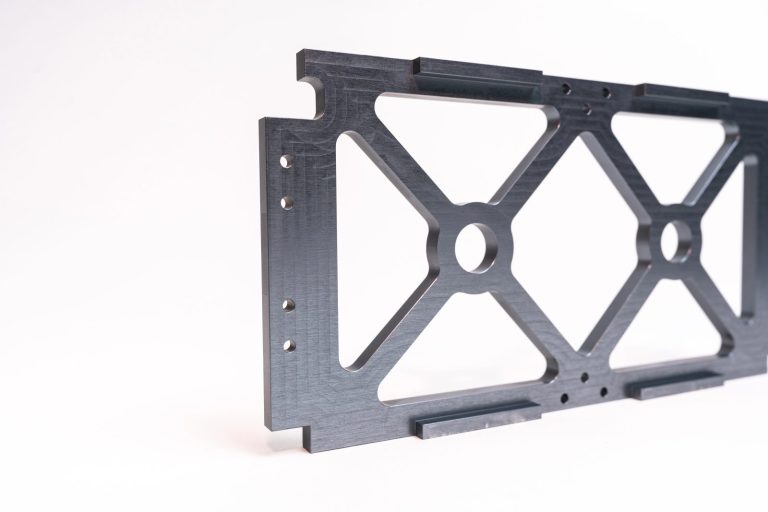

Complex parts processing:

To meet the design standards and ensure optimal function and performance, CNC machining is the ideal choice for parts with complex geometry and high internal structure requirements. It enables accurate processing operations, including milling, drilling, and threading, providing the necessary precision.

Quality control and stability:

CNC machining plays a crucial role in enhancing the quality and consistency of products by minimizing human errors through program control and automation.cnc machining set This is especially vital for industries like aerospace and medical devices that demand stringent quality control measures.cnc machining set

Innovation and design optimization:

CNC machining plays a crucial role in enhancing the quality and consistency of products by minimizing human errors through program control and automation.cnc machining set This is especially vital for industries like aerospace and medical devices that demand stringent quality control measures.cnc machining set