CNC Turning

Our comprehensive CNC Turning services will support you throughout your machining project, from prototype construction to the manufacture of the final part.

Professional CNC Turning Team

Can be manufactured around the clock, 7 days a week

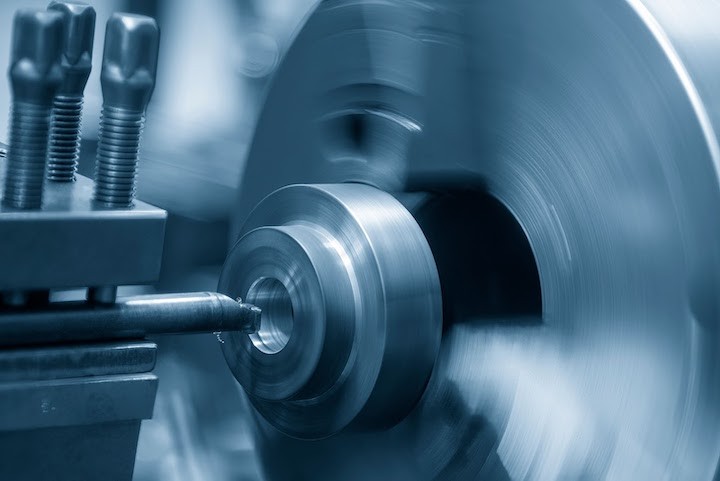

CNC turning services provide an extensive technology for producing cylindrical components from a variety of materials. In contrast to CNC milling, CNC turning involves rotating the workpiece while introducing a stationary tool. Enhanced CNC turning centers enhance this process by incorporating milling capabilities.

We will present a comprehensive overview of the CNC lathe machine, including standard naming conventions, operational procedures, available operations, and the key components of a CNC turning machine.

CNC Turning Explained

CNC turning is a subtractive manufacturing process that involves removing material from a cylindrical stock piece. However, CNC turning can also be applied to various stock shapes like hex or square bars. During the process, the machine rotates the workpiece while a tool cuts and eliminates material until the desired shape is attained. Turning machines can be either vertical or horizontal, with the figure illustrating the axis convention for both types (6 axes displayed, but the actual number may differ). Vertical CNC turning is commonly utilized for machining large and heavy designs due to the alignment of the material’s center of gravity along the rotational axis.

Manufacturing Of Customed Parts

Horizontal CNC turning involves mounting the workpiece in a manner that creates a cantilever effect, potentially leading to vibrations in large, heavy pieces that can impact machining quality and pose a risk of damage to the turning machine and tooling. On the other hand, vertical turning presents its own challenges, such as chip evacuation issues that can result in problems like chip recutting and part scratching. Despite these drawbacks, horizontal CNC turning remains the preferred setup.

CNC Lathes vs. CNC Turning Centers

The distinction between a CNC lathe and a CNC turning center lies in their respective capabilities, with a turning center having the ability to perform various operations whereas a lathe is primarily focused on turning. A lathe is specifically engineered for cutting a workpiece in rotation, while turning encompasses the broader concept of rotational cutting processes.

Prior to the introduction of CNC technology, lathe machines were uniform and easily distinguishable. Nevertheless, technological progress has led to the incorporation of numerous new functionalities. As a result, it has become necessary to distinguish between basic CNC machines that carry out tasks akin to traditional lathes, and advanced machines (CNC turning centers) capable of executing turning cuts in more diverse manners.

Certain companies distinguish between the two by considering the machine’s capability to execute toolpath axes. CNC toolpaths can be categorized as 2D, 3D, 4-axis, or 5-axis, which applies to both milling and turning-cutting processes. Lathes are typically 2-axis machines, whereas turning centers are commonly 3-axis, 4-axis, or 5-axis machines. On the other hand, some companies refer to machines that can perform turning cuts, milling, and drilling operations as turning centers.

CNC Turning Machine Components

Lathes are equipped with a spindle connected to the machine’s drive system on one end, while the other end holds the chuck that secures the workpiece for cutting. The chuck typically features three or four jaws, with three jaws being the most commonly used. Four-jaw chucks are suitable for gripping square bars and also allow for off-center turning.

Carbide inserts are commonly used for cutting tools. These inserts are inserted into tool holders, which are attached to the turret using various specialized holders, depending on the tool type. Tools are then indexed as part of the setup process before machining commences.

CNC Turning Tooling Materials

Numerous companies invest substantial resources in researching improved inserts, coatings, and alloys to enhance the longevity and efficiency of tools. It is essential to choose the appropriate insert design based on the material being machined, as using a tool designed for softer materials on a hard material with the same speed and feed values can result in tool breakage or workpiece damage.Crystal orientation is a crucial aspect of materials engineering when it comes to CNC turning tool inserts. By examining magnified images captured through a microscope, one can analyze the individual crystalline regions within the material, referred to as grains. The composition of the material (alloy) and the methods employed during its production or modification, such as heat treatments and other processes, influence the structure, size, and orientation of these grains. It is worth noting that these grain sizes and orientations have a direct correlation with the mechanical properties of the material.

Types of CNC Turning Operations

Turning refers to a variety of operations that can be carried out on a turning center. Below are several commonly used types of turning techniques.

Facing involves cutting a flat surface perpendicular to the rotational axis of the workpiece using a tool mounted in a tool holder on the lathe carriage. The facing tool moves perpendicularly across the part’s rotational axis during the process. It can be done as either a roughing cut or a final pass cut.

The CNC machine turning process involves the elimination of material from the outer diameter of the workpiece. Turning can be executed either parallel to the rotational axis of the part or at an angle to produce a tapered part.

If there is a need for a hole along the rotational axis of the component, a drill is employed. In highly sophisticated turning centers, a hole can be drilled in various orientations, not just restricted to the central axis.

Once a hole has been drilled, there might arise a need to expand its size. The most convenient approach to achieve this is by performing a boring operation, wherein the cutting tool is inserted into the pre-existing hole and eliminates material from the inner wall of the hole.

Threading involves the act of creating threads either within a hole or along the outer diameter of a workpiece.

Grooving is commonly employed to produce features such as O-ring or circlip grooves and perform contouring operations. A grooving tool, also known as a parting-off tool, is utilized to separate the finished part from the workpiece stock.

Knurling creates a diamond-shaped pattern on the outer diameter of a component without cutting the material. Instead, the knurling tool compresses the material to form the pattern. Knurling is commonly employed to enhance the grip of a component.

Advantages of CNC Turning

CNC turning has many advantages, some of which are listed below:

- CNC turning is known for its ability to consistently manufacture highly accurate components due to the automated process that eliminates human error.

- CNC turning is a versatile manufacturing technology that enables the production of a diverse array of intricate components. Taking it a step further, CNC turning centers integrate milling and turning functionalities, enhancing the overall flexibility of the process.

- Safety is ensured as all cutting operations are conducted behind a machine guard, ensuring that the operator is always at a safe distance from the rotating material. This eliminates any potential risks that are commonly associated with manual turning machines.

- CNC turning machines are capable of delivering quicker results due to their ability to seamlessly execute precise instructions without any interruptions. Moreover, these machines allow for swift tool changes whenever necessary, further enhancing their efficiency.

We will Continue to Forge Ahead in CNC Turning

Now that you possess a more comprehensive comprehension of the fundamentals of CNC lathes and the operations of these machines, should you require CNC turning parts for your upcoming project, MXY provides a variety of CNC turning and milling services through their online CNC service. Therefore, establish an account and submit your parts today! Our internal specialists will furnish complimentary DFM feedback on your design and offer manufacturing advice to guarantee prompt delivery of the necessary quality parts.