It is impossible to envision the contemporary industry without the presence of plastic.oem cnc turned plastic parts cnc machining pom The manufacturing and processing of modern industrial-grade polymers are effortless.cnc vertical machining center vmc640 cnc 3 axis fa These polymers possess significant strength, exceptional resistance to corrosion, and, most importantly, they are remarkably lightweight in comparison to any metal.cnc machining This is the primary reason why they have gained immense popularity among industrial designers. As a result of this widespread popularity, the technology for plastic prototyping has been advancing over the course of several decades. Let us explore the current offerings of this technology.titanium machinery cnc machining parts hollow stee

Plastic prototyping today

Plastic production has historically been associated with mass production.xiamen cnc machining An injection mold and an injection machine are necessary for the plastic to be injected into the mold.robotics cnc machining The entire process is quite costly, and any modifications to the system design can be very expensive.cnc polycarbonate machining This is why metal has traditionally been the preferred material for prototypes, particularly with the advancement of digital systems and computer numerical control machine tools.cnc machining impeller Nevertheless, the introduction of rapid prototyping techniques has brought about a shift in this trend.cnc precision machining custom stainless steel parts

Rapid development of plastic prototypes

The initial advancement involves the utilization of vacuum silica gel casting technology, where soft molds are used in place of hard molds.cnc machining anidado Silicone molds are more cost-effective and simpler to produce.jiangyin cnc machining Subsequently, there is a shift towards cutting-edge additive manufacturing techniques that eliminate the need for any blanks or tools.cnc machining 316 Moreover, these methods provide unmatched design flexibility.Lastly, the CNC machining procedure enables swift plastic injection molding. Aluminum interchangeable molds, as opposed to tool steel, offer enhanced manufacturability and can reduce mold lead time by as much as 60%. Furthermore, replacing the cavity of an aluminum mold is significantly easier compared to a heat-treated steel mold.cnc machining aluminum atm bezel overlay game shel

Table of Contents

Benefits of implementing rapid plastic prototyping

Plastic prototype cost.carbon cnc machining Plastic materials typically have low melting temperatures, good maintainability, and are generally easy to process. This results in the production of plastic prototypes being relatively inexpensive. If you are working with a limited budget, you can simply purchase some silicone, pour it over the master model (which you can create by hand), allow it to set, and then cast the parts at home.cnc machining metal deep insert atm bezel stainles

Durability. Plastic materials exhibit strong durability, boasting good stability, fatigue strength, and friction properties. However, it is important to shield them from UV light and low temperatures, as certain polymers may become brittle under such conditions.custom high precision cnc metal machining 5 axis

Reliability. Plastic prototyping technology has advanced significantly. Many professional injection molding services rely on this technology daily. If you have any inquiries regarding the best method to select and implement, seeking advice from a professional is always a viable option.water jet machining cnc marbel and metal cutting n

Recyclability. The era of plastic pollution being the primary ecological concern is behind us. Modern industrial plastics are designed to be recyclable and do not generate significant hazardous waste during their manufacturing process.cnc machining part cnc machining bearing end cover

Delivery time. Contemporary rapid prototyping techniques are well-suited for producing small batches of plastic parts. In certain instances, you can receive a prototype within a week by utilizing an injection molding service. This efficiency is due to the minimal post-processing required for plastic prototyping.micro machining cnc machining precision machining

Where plastic prototypes can help

Plastic prototype components serve a wide range of purposes beyond the production of kitchenware and household appliances. For instance, numerous medical-grade items are crafted from plastic due to certain polymers’ ability to adhere effectively to human tissue and their lightweight nature. Transparent plastic components are commonly utilized in automotive lighting applications as they are more durable than glass. Additionally, many plastics provide excellent insulation properties, making plastic handles and casings essential for user safety when dealing with heated surfaces or high pressure. Moreover, some polymers with favorable frictional characteristics are employed in the manufacturing of cost-effective bearings.machining plastic cnc machining service

Top 4 quick plastic prototyping options

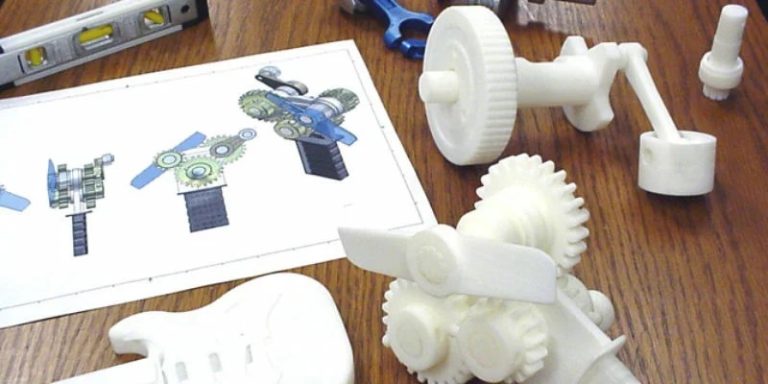

With the rapid development of manufacturing, casting, 3D printing, injection molding and CNC machining. These technologies are based on fast, 3D CAD based prototyping tools that are already widely used in plastic parts.cnc machining/nc turning/precision machining

1.Casting technology for plastic prototype manufacturing

Silica gel casting proves to be an effective method for producing small quantities of plastic prototypes, as it necessitates a master model to form a mold. Typically, the master model is suspended above an empty tank. Subsequently, various technical components, often made of plastic, are incorporated into the model, including channels for plastic pouring and ventilation. Following this, liquid silicone is poured into containers and allowed to solidify, occasionally undergoing curing in an oven. By splitting the mold in half, it becomes possible to generate a maximum of 25 plastic parts. Notably, this process does not demand any initial capital investment.cnc machining/nc turning/precision machining/stain

2.How to use 3D printing for plastic prototyping

Additive manufacturing, also known as 3D printing, is an innovative manufacturing process used to create various parts. Unlike traditional manufacturing methods, 3D printing involves building up the part layer by layer using either powdered materials or thin lines. This process allows for greater precision, improved surface finish, and the ability to select different materials for production. Additionally, additive manufacturing has significantly reduced lead times compared to conventional manufacturing techniques. Since its inception in the 1980s, additive manufacturing has made significant advancements in terms of quality and efficiency.oem micro machining aluminum alloy cnc machining

Selective laser sintering represents the initial among numerous additive manufacturing methods for quickly creating prototypes out of plastics. It stands out as the most adaptable form of additive manufacturing and is applicable to a wide range of materials, plastics included. Minimal laser power is needed to fuse them together, and a key benefit of spreading the powder over the base material is that it can serve as a partial support structure for any protruding features.cnc machining/five-axis machining/dragon head craf

Fused Deposition Modeling (FDM) is considered the most cost-effective and straightforward additive manufacturing method for producing plastic prototypes. It is common for enthusiasts to construct FDM 3D printers in their own homes. FDM involves utilizing plastic filaments as raw materials, melting them, and depositing them layer by layer to form the desired part. To support any overhanging structures, a different type of plastic, which is more fragile and easier to remove, is used. While FDM is known for its affordability, it tends to result in lower surface quality compared to other methods. For projects where aesthetics are crucial, additional finishing processes may be necessary.sky-cnc cnc machining

SLA is often regarded as the pioneer of all 3D printing techniques, boasting the highest quality components in the process. The surface finish is exceptionally smooth, and the precision is solely dependent on the UV/laser diameter. This method is commonly utilized in producing master models for future casting and aesthetically-driven prototypes. Nevertheless, SLA stands out as the most costly process due to the expensive nature of liquid polymers, necessitating a substantial amount to be poured into the tank. Additionally, a notable drawback of SLAs is the support structure, which can solely be crafted from model materials and necessitates removal through mechanical methods. This removal process may result in imperfections on the surface, necessitating post-treatment.

Multi-jet printing is a widely favored method for plastic prototyping due to its numerous benefits similar to FDM, while avoiding certain drawbacks of the SLA technique. The main objective of MJP is to liquefy the raw plastic material into droplets and eject them through the printer’s nozzle based on the specified design. One key advantage of MJP is that the part quality is comparable to SLA, without the need to deal with a large tank of liquid polymer and its disposal. Additionally, MJP stands out as the sole multi-color process among the mentioned methods.cnc service cnc custom machinery machining

Post-processing of 3D printed prototypes

In spite of the advancements made in additive manufacturing, plastic parts often necessitate post-processing. Common methods for this include machining, polishing, and chemical processes. The initial technique is relatively straightforward, involving the installation of the manufactured part into a machine tool and processing it with a milling machine. Polishing is a well-known process that utilizes specialized poultices and instruments to achieve a flawless surface finish. Chemical processes encompass acetone processing and coating. Acetone processing involves the use of gaseous acetone to melt the part’s surface, resulting in a smoother finish. While this method is highly efficient, it is only suitable for a limited range of polymers. On the other hand, coating is a more versatile approach. It entails covering the part with paint or another substance to enhance the surface quality.keyboard cnc case cnc machining set

3.How to create plastic prototypes through rapid injection molding

Rapid plastic injection molding is a modified version of the conventional injection mold manufacturing technology. The primary distinction lies in the specific aspects. For instance, rapid molds possess a greater number of joints. The mold cavity is linked to the base, enabling easy modification of the design by simply removing the cavity and making the necessary changes without affecting other components. This may result in reduced precision but offers enhanced flexibility. Additionally, instead of utilizing hardened steel suitable for numerous iterations, aluminum alloys are employed. Although they are less durable, they are five times more suitable for manufacturing. These alterations enable the utilization of plastic injection molding for prototypes as well. However, it is advisable to employ this technique for projects requiring the utmost quality, as the process remains relatively costly.cnc car parts cnc metal machining part

4.Use CNC machining to manufacture plastic parts

Many plastic prototyping manufacturers utilize CNC machining to test the shape, fit, and function of plastic parts in the field of prototyping. At Wekken, we employ CNC prototyping technology to produce plastic prototypes and metal parts, allowing your design team to accurately simulate the final product’s appearance and functionality. This approach also facilitates the evaluation of assembly work effectiveness and provides ample time and space for design modifications and optimizations.precision cnc machining custom machined cnc preci

The future of rapid plastic prototyping

Most experts anticipate that additive manufacturing will dominate a greater portion of the prototype manufacturing industry in the coming years. This is mainly due to its ideal suitability for the task at hand. Further enhancements in printing speed and part quality are necessary for its advancement. Addressing the issue of porosity is also crucial. Numerous studies are underway to address the limitations of 3D printing, and unless a new groundbreaking method is introduced, additive manufacturing may emerge as the top choice for plastic prototyping in the upcoming decade. For additional details, please refer to our plastics processing capabilities.cnc machining parts knife cnc 5 axis