Custom CNC machining is now a crucial technology and service in the manufacturing industry today. With CNC (Computer Numerical Control), precise computer programming and advanced machining equipment can meet the high precision, complex shapes, and diverse material processing requirements.

Advantages of custom CNC machining Custom CNC machining is favored mainly due to its unique advantages:

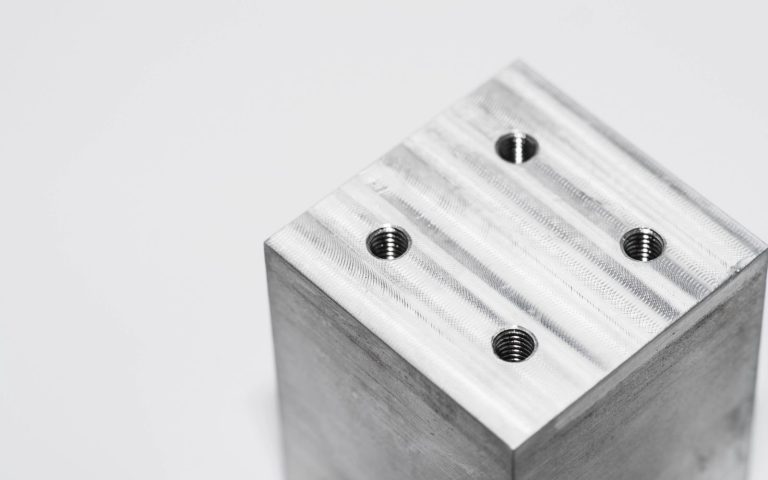

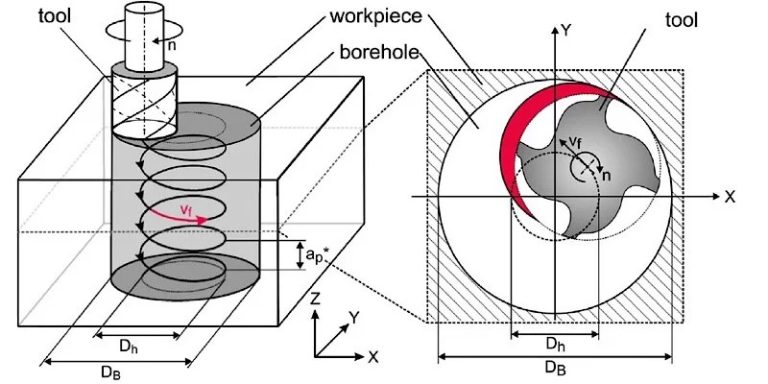

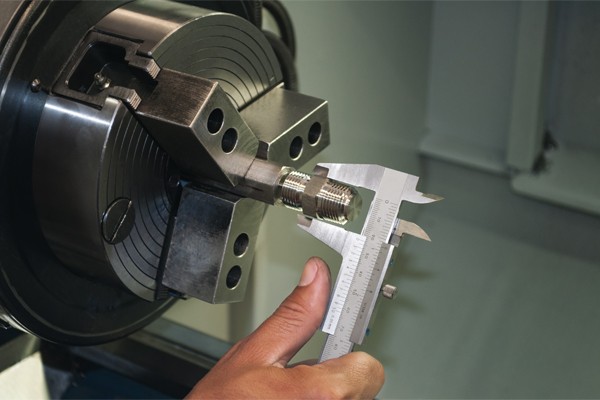

CNC machines are known for their ability to achieve high precision and repeatability by controlling the position and movement of the tool with great accuracy. This ensures that small dimensional changes are processed consistently, resulting in products that are both accurate and consistent.

With its ability to process metal, plastic, wood, and composite materials, CNC machining proves to be adaptable and suitable for various industries like aerospace, medical equipment, and automotive.

CNC machining allows for rapid adjustment and production, reducing the product development cycle significantly compared to traditional methods. This enables customers to quickly meet market demands.

Saving money: While the upfront cost of equipment may be high, CNC machining can ultimately lead to cost savings by lowering scrap rates and enhancing production efficiency, particularly for small and medium-sized batch production.

Application field

Custom CNC machining is essential in various applications, including aerospace. It enables the production of intricate components like turbine blades and structural supports that are crucial in the aerospace industry.

Medical equipment: Tailored medical equipment and prosthetics can be manufactured using CNC machining to ensure precision and compatibility with the body.

The automotive industry focuses on producing various components, including engine and chassis parts, to enhance both performance and safety in vehicles.

Electronic products: The production of precision electronic parts and enclosures to ensure the performance and durability of electronic equipment. Future outlook

The future of custom CNC machining looks bright as technology advances and demand continues to grow. By incorporating artificial intelligence and machine learning, CNC machining is set to become smarter and more adaptable, revolutionizing the manufacturing industry with increased efficiency and innovative capabilities.

Custom CNC machining is more than just a technology – it’s a crucial driving force behind manufacturing advancements. Its precision, versatility, and affordability have propelled its popularity globally and will keep pushing industries to new heights.

Factories are vital in the world of custom CNC machining as they serve as both production sites and essential nodes for implementing technology and meeting customer requirements. They play a significant role in fulfilling various functions in this field.

Technology implementation and equipment investment: By investing in and maintaining advanced CNC machines and related equipment, the factory ensures that customers’ custom needs for a wide range of materials and complex geometry are met. Select the right machining process and tool path to ensure high precision and production efficiency. Process optimization and quality control:

The factory is responsible for developing and optimizing the process flow of CNC machining, including material selection, machining sequence, tool use, etc., to ensure that products can meet the precise requirements of customers. Carry out strict quality control and inspection to ensure that each product meets the design specifications and standards.

Responding to customer needs and project management: The factory provides technical support and advice to customers through close communication with customers to understand and interpret their needs and design intentions. Manage and plan production schedules to ensure timely delivery of customized parts that meet customer expectations.

Flexible production and batch management: According to customer needs and order volume, adjust production plan and resource allocation, can flexibly respond to small batch and mass customization processing needs. Optimize production efficiency and cost control to provide competitive customized CNC machining solutions.

Continuous improvement and technological innovation: Continuous pursuit of process improvement and technological innovation, the introduction of new CNC machining technology and tools to adapt to changes in the market and customer needs. Combined with advanced CAD/CAM software and process simulation, enhance the processing capacity and competitiveness of the plant.

In summary, the factory in custom CNC machining is not only the production site of products, but also the center of technical capabilities and service execution. Through effective technology implementation, quality control, project management and technological innovation, the factory is able to provide customers with high-quality, high-precision custom parts, thereby gaining an advantage in the market competition and achieving continuous growth.