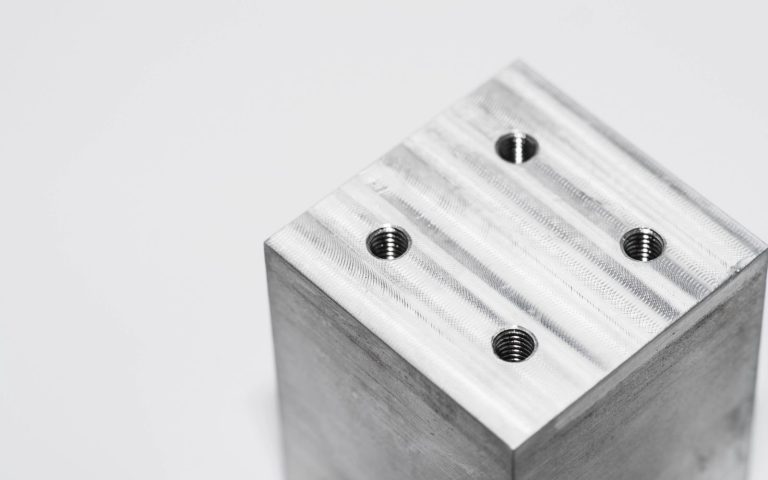

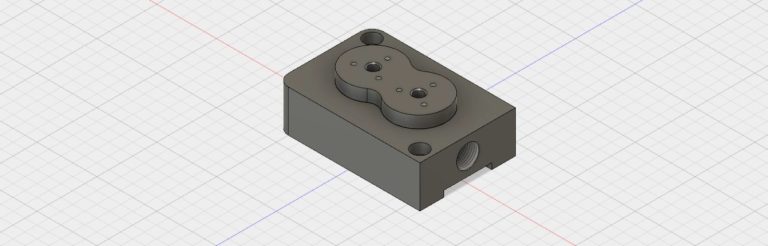

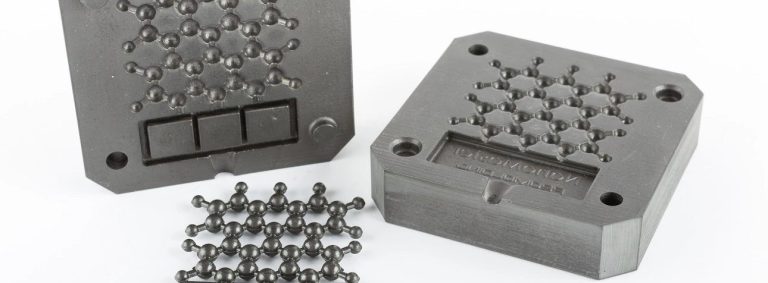

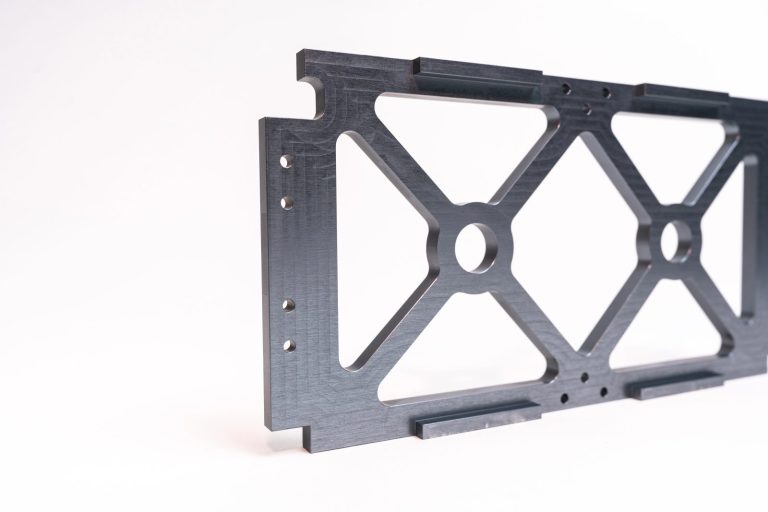

Precision engineering:CNC machining motorcycle accessories

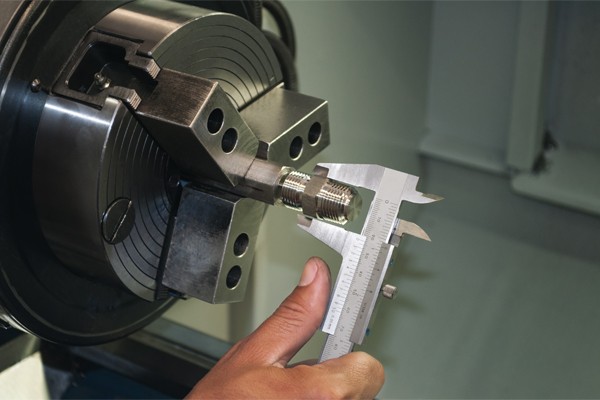

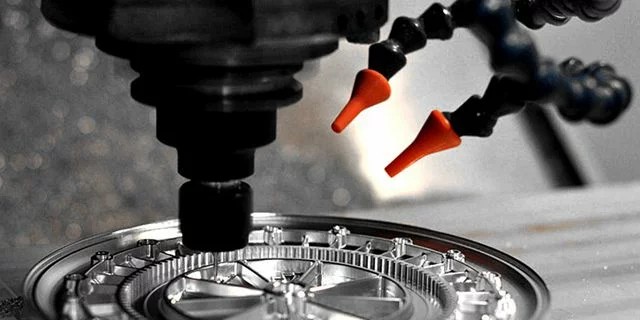

CNC machining of motorcycle accessories: precision and performance In the realm of motorcycles, all riders understand the inseparable connection between performance and style. Whether it’s a need for greater speed or a desire for a more appealing look, there is an increasing desire for top-notch motorcycle accessories. CNC machining plays…