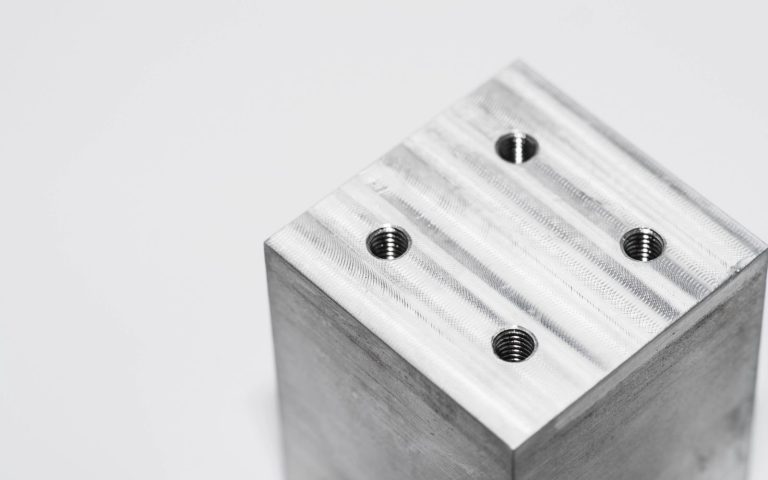

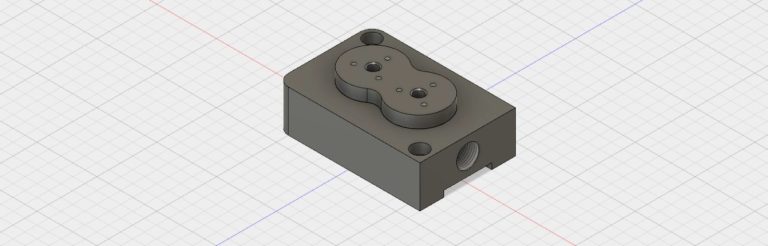

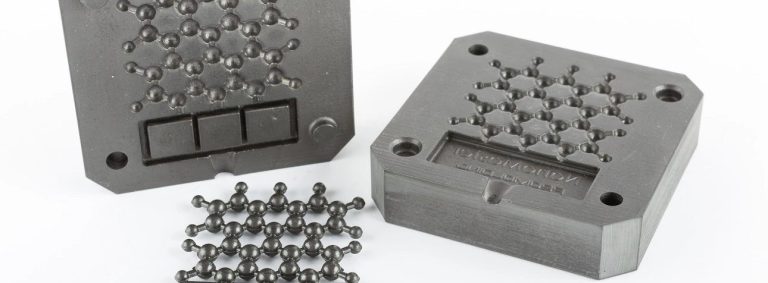

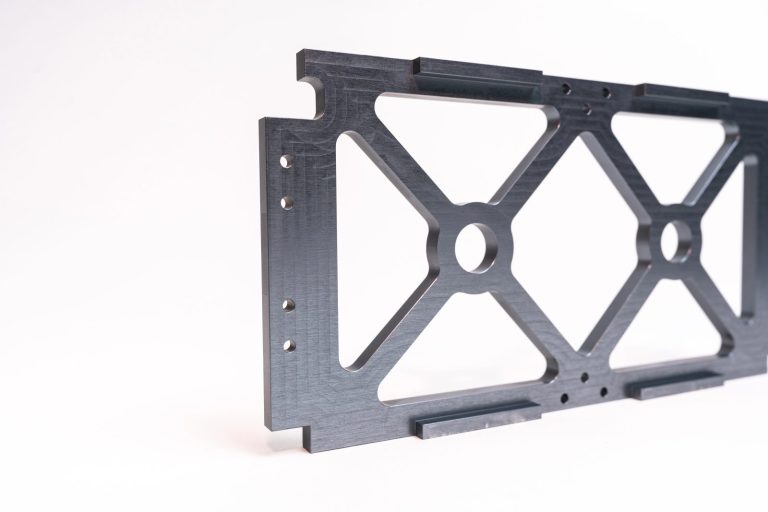

Precision CNC turning services

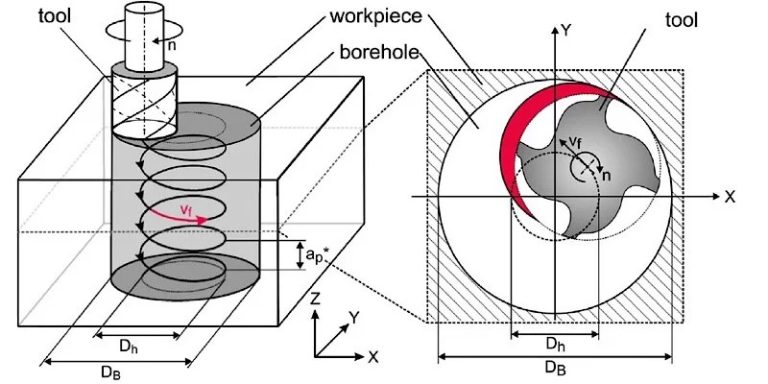

First of all, before diving into the details, you need to understand what precision turning is. Precision turning is the removal of excess material from the workpiece to reduce its size and convert its size to the desired size so that it can fit where we need it. So basically,…

.png)