Welcome To MXY

Tailored Production Services From Prototype Development to Mass Manufacturing

- Quick Prototyping and Custom Manufacturing Available Within Days.

- Distinguishing Between Machining and Molding for Plastic and Metal Components.

- We are one of the top suppliers of precision machining solutions and operate with a high-mix, low-volume business model.

.jpg)

MXY is prepared to transform your concepts into tangible products, offering cutting-edge manufacturing solutions tailored to your specific needs throughout the entire process from design to prototyping to production.

CNC Machining

MXY is also your best manufacturing partner. We offer a range of solutions to help you scale from effective prototypes to production parts. Our rich manufacturing experience and ability to integrate resources enable us to handle any project’s needs and ensure your parts always meet the highest quality standards. Custom rapid manufacturing services include CNC machining, plastic injection molding, metal casting, sheet metal fabrication, and parts finishing.

Rapid Manufacturing

MXY serves as a dependable R&D collaborator. With our efficient processes, we can swiftly transform a CAD design into a tangible prototype that reaches your team promptly. Our cutting-edge rapid prototyping technology is tailored to address your design obstacles, and we are committed to assisting you in validating and enhancing your product concepts, conducting functional tests, and ensuring engineering verification. Our comprehensive range of rapid prototyping services encompasses CNC prototyping, 3D printing, vacuum casting, rapid tooling, sheet metal prototyping, and prototype finishing.

Complete Prototyping & Manufacturing Capabilities

MXY Rapid Manufacturing serves as a comprehensive solution for rapid manufacturing and prototyping needs. Discover the ways in which our company facilitates on-demand parts production and custom manufacturing for your team.

Rapid Prototyping & On-Demand Manufacturing Services.

At MXY, we offer comprehensive rapid prototyping services and affordable rapid manufacturing services to assist with all stages of your product development and expedite your time to market. Whether you require just one unit or more than 10,000 units, production-grade materials, intricate geometric shapes, tight tolerances, or fine details, MXY is committed to fulfilling your design and manufacturing requirements. Our ultimate goal is to bring your concepts to fruition.

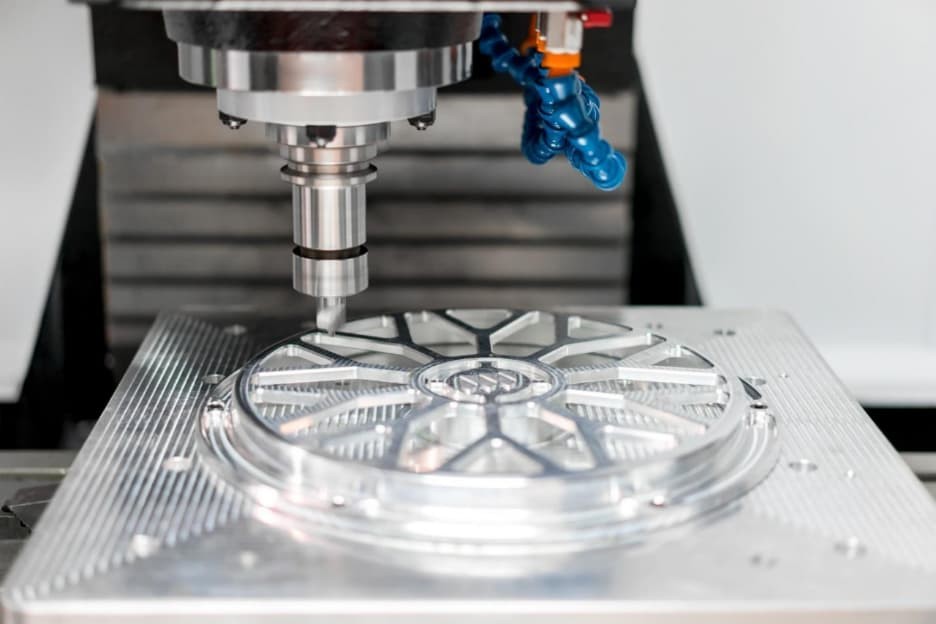

CNC Machining

CNC machining offers an ideal resolution for fabricating custom prototypes and production parts, ensuring compliance with your stringent requirements, including accurate tolerances, unique materials, intricate components, and optimal efficiency.

CNC Aluminum

The CNC aluminum machining process can be optimized for maximum precision and efficiency through the utilization of advanced 3 & 5-axis CNC milling and turning techniques, along with auxiliary processes such as EDM and wire EDM. Additionally, typical aluminum surface finishing methods can further enhance the overall quality of the machining process.

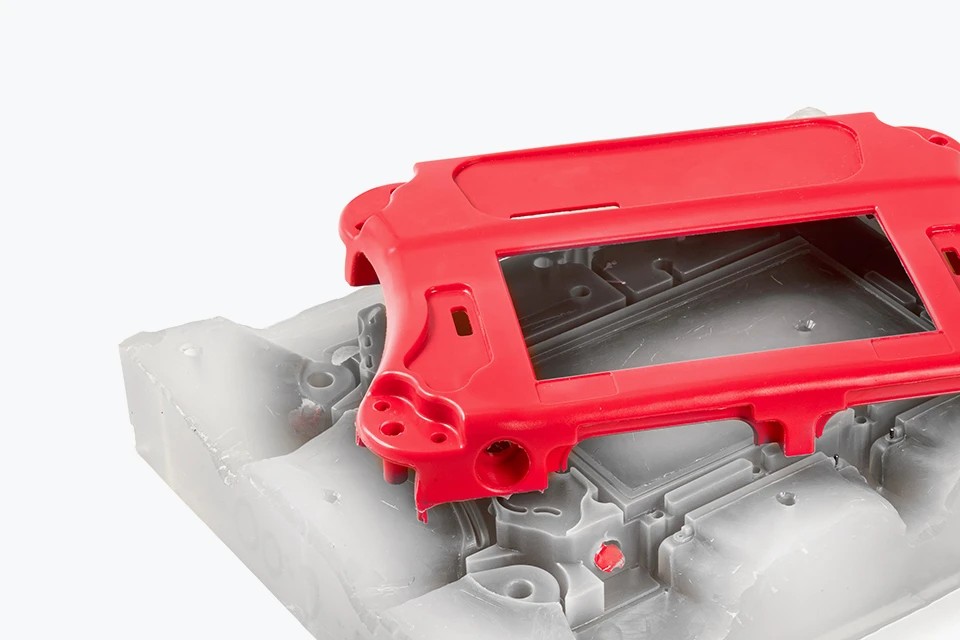

Vacuum Casting

Vacuum casting, also known as urethane casting, offers a rapid method for producing a limited run of operational plastic prototypes, delivering final-use, stiff, pliable, and rubber components with high quality and cost-effectiveness.

Rapid Tooling

Rapid injection molding has the capability to close the divide between prototype and production by facilitating the creation of aluminum and steel rapid molds, as well as enabling low-volume injection molding. This approach aims to achieve reduced tooling expenses and expedited production changeovers.

Selecting the Appropriate Prototype Manufacturer

Our prototype supplier is certified under ISO 9001:2015 standards to guarantee that your project adheres to rigorous quality requirements.

Receive personalized support from our technical team with rapid responses within a short timeframe.

We offer the most competitive prices in the market, which are 30% lower than those in Europe and America.

OUR CUSTOMERS

Industries MXY Serve

MXY provides exceptional on-demand production services on a global scale. Our most valuable resource is our extensive customer network, which has expanded rapidly through positive word-of-mouth from customers worldwide. This network encompasses a wide range of clients, including independent inventors, designers, as well as large-scale Industrial, Commercial, Medical, Automotive, and Aerospace companies.

Automotive

From exterior optical lighting to interior component.

Medical Device

From handheld appliances to large scale treatment units.

Consumer &Commercial

From instruments and equipment to digital appliance.

Industrial Design

Discussion, Optimizing, Evaluation, Verification.

Begin your prototyping and manufacturing journey with us by following our straightforward 4-step process.

24/7 Support for Productions + Prototypes & Parts Fast Global Delivery

01.

Upload Your CAD File

You can either directly upload your file or send your project message through the quote page. Rest assured that all files are protected under a Non-Disclosure Agreement (NDA).

02.

Quote & DFM Analysis

The Design For Manufacture analysis and real-time quote will be returned to you within a 12-hour timeframe.

03.

Start Production

Upon confirmation of the order, we will commence the manufacturing process using your CAD design.

04.

Get Your Parts

Prototypes and components will be manufactured in a matter of days and shipped to you promptly via international express delivery.

From MXY Blog

MXY remains committed to disseminating our expertise and insights in cutting-edge manufacturing practices. Our articles delve into the realm of state-of-the-art rapid prototyping and rapid manufacturing technologies, offering valuable insights to enhance product design and discover superior solutions for new product development.

Why Choose Us

We manufacture cost-effective cNC Machining parts

We have over 20 years’ experience in manufacturing professional CNC machining parts.

Trusted By Over 1,200+ Clients

Worldwide Since 2001

1,262

Clients

20+

years of experience

why choose us

We Help You Competitive in your local market

We have experience in cooperating with overseas distributors or even manufacturers.

Professional Expertise

Your order will be processed ASAP.

Superior Quality

We have world class testing center.

Affordable Price

We use automatic production line to reduce cost.