Product Prototyping

Product prototyping plays a crucial role in the process of developing new products. Whether the goal is to test out fresh product designs or enhance solutions for current products, the product prototype proves to be an invaluable asset.

Why Product Prototype Development?

The corporate strategy of organizations has shifted towards prioritizing the ability to swiftly adapt to market demands, with time being of utmost importance. In this context, the competitiveness of businesses hinges on their ability to swiftly generate new product prototypes in order to validate the designs of product developers and iterate rapidly to introduce fresh product concepts to the market promptly, catering to the preferences of their target demographic.

A product prototype serves as a crucial tool for designers and engineers to ensure that the design aligns with the specifications or requirements outlined during the prototype development phase.

What Type Of Product Prototype Is Needed?

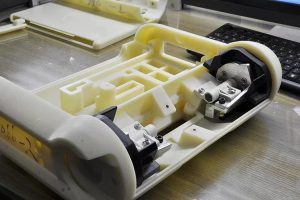

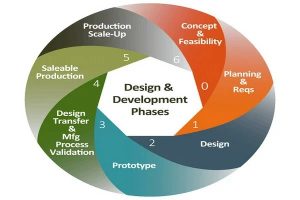

The journey from concept to the first prototype is often considered a complex and lengthy process in product development. It is crucial to validate the feasibility of the idea before proceeding to mass production. Employing suitable prototype techniques can enhance the dynamism and efficiency of product prototyping, thereby minimizing the risk of failure. Product prototypes play a vital role in the entire design and development phase, encompassing physical, visual, working, and low volume manufacturing prototypes.

Significance Of Product Prototypes In Development Process

- Realize And Explore Concepts

Develop product concepts within a feasible framework by focusing on defining key elements and comprehensively grasping the design purpose using proof-of-concept models.

- Communicate Ideas Effectively

Visual presentation models enable designers to communicate their ideas with colleagues, clients, and stakeholders, thereby gaining valuable perspectives and facilitating concise, practical feedback.

- Design Iterations More Flexible

Functional prototype development is a valuable tool for evaluating design iterations and optimizing the performance of your product, ultimately leading to the attainment of the final design. By identifying and rectifying any potential issues early on, it allows for a reduction in business plan risk.

- Move To Full Production With Confidence

Developing a functional prototype that aligns with the end product simplifies the process of validating the design, engineering, and feasibility prior to committing to costly equipment and initiating production.

- Cost-Effective Low Volume Manufacturing

Rapid tooling and customized low-volume manufacturing can help close the gap between prototyping and full-scale production, enabling your product to reach the market quickly and cost-effectively.

.png)