3D Printing Services

By integrating rapid prototyping techniques in CNC machining, EDM machining, 3D printing, vacuum casting, and finishing processes within product development, MXY is capable of efficiently producing rapid production tooling and injection molds in a timely manner.

What Is 3D Printing Prototype?

3D Printing, also known as additive manufacturing, encompasses various rapid prototyping techniques that involve layering materials to produce components. Rapid prototyping through 3D printing offers a fast, efficient, and economical method for transforming innovative concepts into marketable goods. These prototypes not only validate designs but also identify potential problems at an early stage, enabling prompt adjustments and averting expensive alterations during mass production.

Why Choose MXY For 3D Printing Service?

MXY specializes in rapid prototyping manufacturing in China and offers a diverse range of 3D printing services, such as Stereolithography (SLA) and Selective Laser Sintering (SLS). Our team at MXY consists of skilled engineers and project managers who are committed to verifying your CAD designs, ensuring product functionality and dimensional tolerances. As a reputable prototype manufacturer, we have a comprehensive understanding of the prototype and production requirements for businesses.

Benefits Of 3D Printing

- Accelerate Delivery Times. Components can be shipped within a short span, expediting design iterations and time to market.

- Enable Complex Geometry. Facilitates the production of distinctive parts with intricate geometries and precise details, all while keeping costs in check.

- Minimize Manufacturing Expenses. Strive to lower production costs by eliminating the necessity for tools and reducing labor requirements.

Ready to Start Making 3D Printed Prototypes?

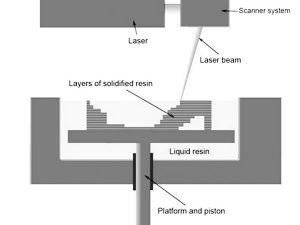

What Is SLA 3D Printing?

SLA 3D Printing, also known as Stereolithography, employs an ultraviolet laser to trace the liquid thermoset resin’s surface, resulting in the formation of final parts through the accumulation of numerous thin layers. SLA 3D Printing offers a diverse range of materials, exceptional feature resolutions, and impeccable surface finishes.

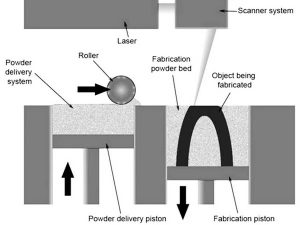

What Is SLS 3D Printing?

SLS 3D Printing, also known as Stereo Laser Sintering, utilizes a powerful optic laser to fuse fine powder particles together in a layered manner, resulting in the creation of intricate and long-lasting geometric components. This advanced printing technique constructs sturdy parts using Nylon materials, making it ideal for both functional prototypes and final products.

How Does SLA 3D Printing Work?

The proprietary software’s slicing program imports the 3D Model for data processing, while adding necessary support structures. Subsequently, the STL file is transmitted to the SLA machine, where it is printed using a tank filled with liquid photosensitive resin. A building platform is then gradually lowered into the resin-filled tank. By focusing the UV laser beam through the lens, the contour of each cross-section is scanned along the liquid surface. This scanning area causes the resin to solidify rapidly, resulting in the formation of a single layer of material. Once the first layer is completed, the platform is lowered by 0.05–0.15mm, and a fresh layer of resin is applied to cover the build surface. The process is repeated for each subsequent layer, as the resin cures and bonds to the layer below, ultimately constructing the final part.

How Does SLS 3D Printing Work?

The powder is spread thinly on a platform within a chamber. When heated slightly below the polymer’s melting point, a laser beam scans the powder based on the layer’s contour and sinters it. The unsintered powder acts as support for the model’s cavity and cantilever. After each cross-section is sintered, the platform’s thickness decreases by one layer, and a roller lays down a new layer of powder for the next cross-section. This cycle continues until all layers are sintered, resulting in a solid model.

.png)